Narkewar Hasken Wutar Lantarki(EBM)

Electron Beam Selective Melting (EBSM) Ka'ida

Kama da Laser selective sintering daNarkewar Laser ZaɓaɓɓenFasahar narkewar wutar lantarki (EBSM) fasahar masana'anta ce mai sauri wacce ke amfani da katako mai ƙarfi da sauri don zaɓin foda na ƙarfe, ta haka narke da samar da kayan foda.

Hanyoyin ciniki na EBSM fasaha shine kamar haka: na farko, yada wani Layer na foda a kan foda mai yada foda;sannan, a karkashin sarrafa kwamfuta, za a narkar da igiyar wutar lantarki bisa ga bayanan bayanan da ke cikin sassan sassan, sannan a narkar da foda na karfe tare, a hade shi da bangaren da aka kafa a kasa, sannan a tara shi har sai da gaba daya bangaren ya cika gaba daya. narke;A ƙarshe, ana cire foda mai yawa don samar da samfurin mai girma uku da ake so.Ana watsa siginar siginar na'urar daukar hotan takardu na babbar kwamfuta zuwa ga karkarwar karkata bayan dijital-zuwa-analog juzu'i da haɓaka wutar lantarki, kuma wutar lantarki tana jujjuyawa a ƙarƙashin aikin filin maganadisu da ke haifar da wutar lantarki mai dacewa don cimma zaɓin narkewa. .Bayan fiye da shekaru goma na bincike, an gano cewa ana aiwatar da wasu sigogi na tsari irin su electron beam current, mayar da hankali kan halin yanzu, lokacin aiki, kauri na foda, haɓaka ƙarfin lantarki, da yanayin dubawa a cikin gwaje-gwajen orthogonal.Lokacin aiki yana da tasiri mafi girma akan samuwar.

AmfaniFarashin EBSM

Fasahar ƙera ƙarfe kai tsaye na lantarki yana amfani da igiyoyin lantarki masu ƙarfi a matsayin tushen sarrafa zafi.Ana iya yin sikanin ƙirƙira ba tare da inertia na inji ba ta hanyar sarrafa na'urar maganadisu ta jujjuyawar maganadisu, kuma mahalli na katako na lantarki kuma na iya hana foda na ƙarfe daga iskar oxygen a lokacin ɓarna ko narkewa.Idan aka kwatanta da Laser, lantarki katako yana da abũbuwan amfãni daga high makamashi amfani kudi, babban mataki zurfin, high abu sha kudi, kwanciyar hankali da kuma low aiki da kuma kula halin kaka.Fa'idodin fasahar EBM sun haɗa da haɓakar haɓakar haɓaka, ƙarancin ɓarna, rashin buƙatar tallafin ƙarfe yayin aiwatar da tsari, ƙananan ƙananan ƙananan, da sauransu.Juyawar katako na lantarki da sarrafa mayar da hankali yana da sauri da kulawa.Juyawar na'urar tana buƙatar yin amfani da madubi mai girgiza, kuma saurin jujjuyawar madubin yana da matuƙar sauri idan na'urar ta duba cikin sauri.Lokacin da ƙarfin laser ya karu, galvanometer yana buƙatar tsarin sanyaya mafi rikitarwa, kuma nauyinsa yana ƙaruwa sosai.Sakamakon haka, lokacin amfani da sikanin wutar lantarki mafi girma, za a iyakance saurin binciken Laser.Lokacin duba babban kewayon ƙirƙira, canza madaidaicin tsayin laser shima yana da wahala.Juyawa da mayar da hankali na katakon lantarki ana cika su ta filin maganadisu.Za'a iya sarrafa jujjuyawar da tsayin tsayin daka na katako na lantarki da sauri da hankali ta hanyar canza ƙarfi da alkiblar siginar lantarki.Tsarin karkatar da bim ɗin lantarki ba zai dame shi ta hanyar ƙafewar ƙarfe ba.Lokacin narkewar ƙarfe tare da lasers da katako na lantarki, tururin ƙarfe zai bazu ko'ina cikin sararin samaniya kuma ya rufe saman kowane abu da ke hulɗa da fim ɗin ƙarfe.Juyawa da mayar da hankali na katako na lantarki duk ana yin su ne a cikin filin maganadisu, don haka ƙafewar ƙarfe ba zai shafe su ba;Na'urorin gani kamar Laser galvanometers ana samun sauƙin gurɓata su ta hanyar evaporation.

Laser Nital Zubar da ciki(LMD)

Laser Metal Deposition (LMD) da Sandia National Laboratory a Amurka ne ya fara samar da shi a cikin 1990s, sannan ya ci gaba a jere a yawancin sassan duniya.Tun da yawancin jami'o'i da cibiyoyi suna gudanar da bincike na kansu, wannan fasaha Akwai sunaye da yawa, kodayake sunayen ba iri ɗaya ba ne, amma ka'idodinsu ɗaya ne.A lokacin gyare-gyaren tsari, ana tattara foda a kan jirgin da ke aiki ta hanyar bututun ƙarfe, kuma ana kuma tattara katako na Laser har zuwa wannan batu, kuma foda da matakan aikin haske sun yi daidai, kuma ana samun mahaɗin da aka ɗora ta hanyar motsawa ta hanyar aikin aiki. ko nozzle.

Fasahar LENS yana amfani da Laser-class kilowatt.Saboda babban wurin mayar da hankali na Laser, gabaɗaya sama da 1mm, kodayake ana iya samun abubuwan haɗin ƙarfe na ƙarfe mai ƙarfi, daidaiton girman su da ƙarewar saman ba su da kyau sosai, kuma ana buƙatar ƙarin injin kafin amfani.Laser cladding wani hadadden tsari ne na zahiri da sinadarai, kuma ma'auni na tsarin sutura suna da babban tasiri akan ingancin sassan da aka rufe.A tsari sigogi a Laser cladding yafi hada da Laser ikon, tabo diamita, defocusing adadin, foda ciyar gudun, Ana dubawa gudun, narkakkar pool zazzabi, da dai sauransu, wanda da babban tasiri a kan dilution kudi, crack, surface roughness da compactness na cladding sassa. .Hakazalika, kowane ma'auni kuma yana shafar juna, wanda tsari ne mai rikitarwa.Dole ne a yi amfani da hanyoyin sarrafawa da suka dace don sarrafa abubuwa masu tasiri daban-daban a cikin kewayon da aka yarda da tsarin sutura.

Kai tsayeKarfe Laser Sintering(DMLS)

Akwai yawanci hanyoyi guda biyu donSLSdon kera sassan ƙarfe, ɗaya ita ce hanyar kai tsaye, wato, SLS na foda mai rufi na polymer;ɗayan ita ce hanyar kai tsaye, wato Direct Metal Laser Sintering (DMLS) .Tun lokacin da aka gudanar da bincike kan laser sintering na karfe foda a Jami'ar Chatofci da ke Leuvne a 1991, kai tsaye ta hanyar yin amfani da foda na karfe don samar da sassa uku masu girma. ta tsarin SLS yana ɗaya daga cikin maƙasudin maƙasudin saurin samfur.Idan aka kwatanta da fasahar SLS kai tsaye, babban fa'idar tsarin DMLS shine kawar da tsada da ɗaukar lokaci kafin magani da matakan aiwatar da magani.

Siffofin Farashin DMLS

A matsayin reshe na fasahar SLS, fasahar DMLS tana da tushe iri ɗaya.Koyaya, yana da wahala a samar da sassan ƙarfe daidai gwargwado tare da sifofi masu rikitarwa ta hanyar fasahar DMLS.A cikin bincike na ƙarshe, ya fi girma saboda tasirin "spheroidization" da kuma lalata ƙwayar foda na karfe a cikin DMLS.Spheroidization wani al'amari ne a cikin abin da surface siffar narkakkar ruwa ruwa canza zuwa wani mai siffar zobe surface a karkashin interfacial tashin hankali tsakanin ruwa karfe da kewaye domin yin tsarin hada da saman narkakkar ruwa ruwa da kuma saman matsakaicin da ke kewaye da mafi ƙarancin makamashi kyauta.Spheroidization zai sa foda na karfe ya kasa yin ƙarfi bayan narkewa don samar da ruwa mai ci gaba kuma mai santsi, don haka sassan da aka kafa suna sako-sako da suttura, wanda ke haifar da gazawar gyare-gyare.Saboda da in mun gwada da high danko na guda-bangaren karfe foda a cikin ruwa lokaci sintering mataki, da "spheroidization" sakamako ne musamman tsanani, kuma mai siffar zobe diamita ne sau da yawa ya fi girma fiye da diamita na foda barbashi, wanda take kaiwa zuwa babban adadin. pores a cikin sintered sassa.Sabili da haka, DMLS na foda na ƙarfe guda ɗaya yana da lahani na tsari, kuma sau da yawa yana buƙatar magani na gaba, ba ainihin ma'anar "sintering kai tsaye ba".

Domin shawo kan "spheroidization" sabon abu na guda bangaren karfe foda DMLS da sakamakon tsari lahani kamar sintering nakasawa da sako-sako da yawa, ana iya samun gaba ɗaya ta amfani da Multi-bangaren karfe foda tare da daban-daban narkewa maki ko amfani da pre-alloying powders. .A Multi-bangaren karfe foda tsarin ne gaba ɗaya hada da high narkewa batu karafa, low narkewa batu karafa da wasu kara abubuwa.Babban foda mai narkewa kamar karfen kwarangwal na iya riƙe da ƙarfi a cikin DMLS.Ana amfani da foda mai ƙarancin narkewar ƙarfe azaman ƙarfe mai ɗaure, wanda aka narke a cikin DMLS don samar da wani lokaci na ruwa, da kuma sakamakon ruwan lokaci na riguna, jika da ɗaure ƙaƙƙarfan ɓangarorin ƙarfe na zamani don cimma ƙarancin ƙima.

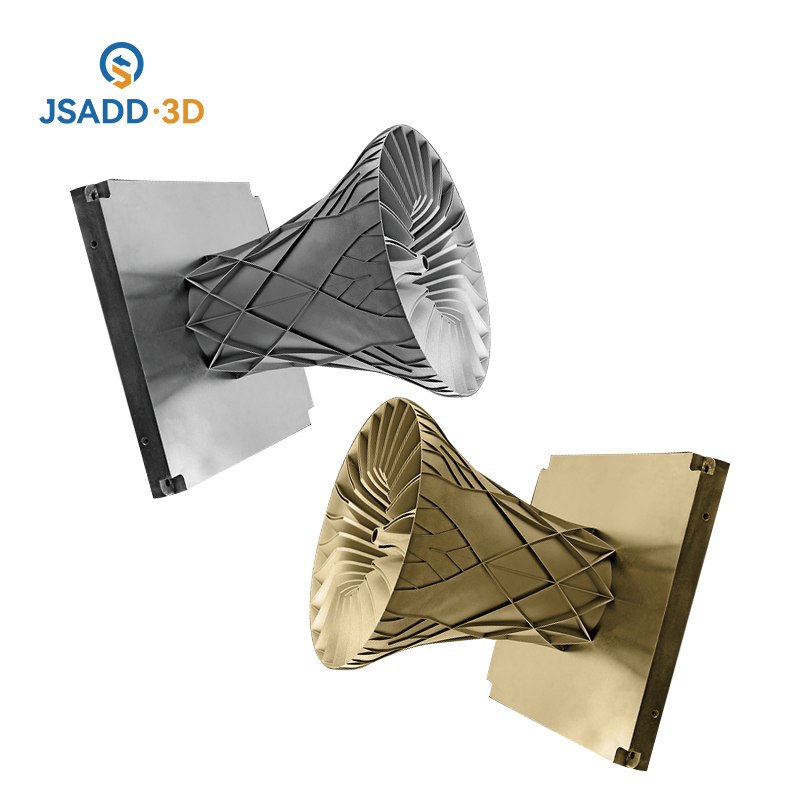

A matsayin babban kamfani a kasar SinSabis na bugu na 3Dmasana'antu,JSADD3D ba zai manta da ainihin manufarsa ba, ƙara zuba jari, ƙirƙira da haɓaka ƙarin fasahohi, kuma ya yi imanin cewa zai kawo sabon ƙwarewar bugu na 3D ga jama'a.

Mai ba da gudummawa: Sammi