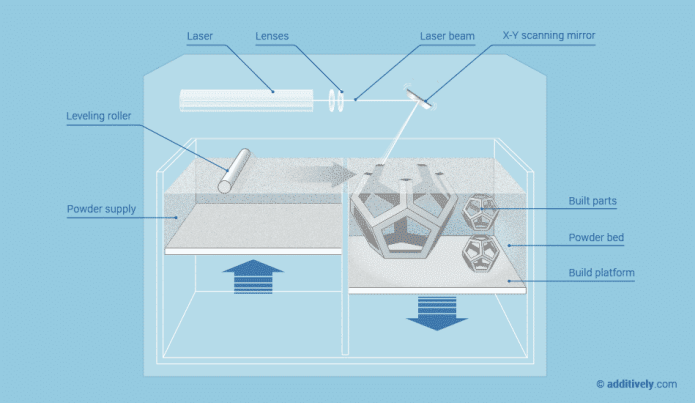

Zaɓaɓɓen Laser Sintering (SLS)fasaha ce mai ƙarfi ta 3D mai ƙarfi wacce ke cikin dangin foda gado fusion tsarin iyali wanda zai iya samar da madaidaici kuma sassa masu ɗorewa waɗanda za a iya amfani da su kai tsaye don amfani da ƙarshe, ƙananan samar da tsari ko sassan samfuri.A lokacin aikin bugu na na'urar SLS, ƙananan barbashi na foda na filastik suna narke a cikin siffar mai girma uku da ake so ta amfani da laser mai ƙarfi.Laser selectively fuses fodakayan aikita hanyar duba sashin bayanai mai girma uku na saman gadon foda.Bayan an duba kowane ɓangaren giciye, ana saukar da gadon foda da kauri ɗaya, ana ƙara sabon nau'in kayan a ciki, kuma ana maimaita tsarin simintin laser ɗin har sai ɓangaren ya cika.

SLS 3D buguza a iya amfani da duka biyu domin prototyping aikin polymer aka gyara da kuma kananansamar da gudusaboda girman girmansa na yanci na ƙira, babban madaidaici, da kuma samar da sassa masu kyau da daidaiton kayan aikin injiniya.Kamar yadda hoto mai zuwa ya nuna:

1.Tsarin Bugawa

1.Tsarin Bugawa

① Na farko, silo da ginin ginin suna mai zafi don rufe yanayin zafi na narkewaabu, kuma an shimfiɗa kayan foda.

② Ana amfani da Laser don bincika sashin giciye na wannan Layer, a ɗaga zafin foda zuwa wurin narkewa, sannan a zaɓi wurin da za a buga don samar da haɗin gwiwa.

③ Bayan sintering, ginin dandali ya motsa ƙasa, an rufe shi da wani nau'i na kayan foda, kuma abin da ke cikin mataki na biyu yana maimaita har sai an kafa samfurin gaba ɗaya.

④ Sannan bayan bugu, ɗakin da aka kafa yana kwantar da hankali (yawanci ƙasa da digiri 40), kuma yana iya fara cire sassan don aiki na gaba.

2. Features

Babban fa'idar SLSshine cewa baya buƙatar tsarin tallafi.Foda wanda ba a haɗa shi ba yana ba da duk goyon bayan da ake bukata don sashi.Sabili da haka, ana iya amfani da SLS don ƙirƙirar siffofi na geometric kyauta, idan dai yana cikin ma'auni na tsarin bugawa, masu zanen kaya na iya amfani da basirarsu kamar yadda suke so, ba tare da damuwa da masana'antu ba.

Lokacin da ake bugawa tare da SLS, musamman don ƙananan ƙananan kayan aiki, yana da mahimmanci don yin amfani da mafi yawan ƙarfin ginin duka da kuma ƙara sawun bugu (matsayin ƙarar samfurin da aka buga a cikin dukan bugu).Bayan ƙayyade matsakaicin tsayin bugawa dangane da buƙatun shimfidar samfuran da aka buga, zai ɗauki kusan adadin lokaci ɗaya don bugawa, ba tare da la'akari da adadin samfuran da aka buga a cikin sarrafa bugun ba.Wannan shi ne saboda saurin yaduwa na kowane Layer yana ƙayyade jimlar lokacin bugawa (na'urar sikanin laser yana faruwa da sauri), kuma injin zai yi zagaya ta hanyar adadin nau'ikan.

Saboda haka, ga masana'anta da ke samarwaSLSaiwatar da ayyukan bugu na 3D, yana iya amfani da adadi mai yawa na umarni, da haɓaka haɗin samfuran da aka ba da umarni gwargwadon yiwuwa a cikin ɗakunan bugu guda ɗaya don samarwa, wanda zai rage farashin bugu da haɓaka saurin bugawa.(Rage lokacin jiran umarni da yin umarni, da sauri fara samarwa).

3. La'akari da ƙira mai nauyi

Tunda SLS baya bukata kayan tallafi, Za a iya buga sassa tare da sassa mara kyau a sauƙaƙe kuma daidai.

Bangaren da ke cikin rami yana rage nauyi da tsadar sashin saboda ana amfani da ƙasa kaɗan, wanda ke da mahimmanci musamman a sararin samaniya.Sabili da haka, yayin zayyana sashin, ko lokacin sarrafa bayanai kafin bugawa, ya zama dole a yi la'akari da ramukan tserewa na foda don cire foda mara tushe daga cikin sashin (wanda ke taka rawa a cikin tsarin sintepon). ).Ana ba da shawarar ƙara aƙalla 2 mafi ƙarancin 5 mm diamita na tserewa ramuka zuwa ƙirar ku.

Idan ana buƙatar tauri mai girma, dole ne a buga ɓangaren gabaɗaya.Wani zaɓi shine yin ƙira mara kyau, barin ramin tserewa.Ta wannan hanyar, za a kama foda da aka ɗora a cikin ɓangaren, yana ƙaruwa da yawa kuma yana ba da ƙarin tallafi a kan kayan aikin injiniya ba tare da rinjayar lokacin ginawa ba.Za'a iya ƙara tsarin grid na saƙar zuma na ciki zuwa cikin rami mara kyau don ƙara taurin ɓangaren.

4.Amfani da iyakoki

a) Babban fa'idodi

b) Sassan SLS suna da kyawawan kaddarorin injiniya na isotropic, suna sanya su manufa don sassan aiki da samfura.

c) SLS baya buƙatar kowane tallafi kuma yana iya samar da kayayyaki cikin sauƙi tare da hadaddun geometries.

d) The masana'antu damar naSLSsu ne manufa domin kananan da matsakaici-sized tsari samar.

② Babban rashin amfani:

a) Ƙunƙarar saman ƙasa da ƙarancin ciki na sassan SLS na iya buƙatar aiwatarwa bayan aiki idan ana so mai santsi ko ruwa.

b) Ƙaƙƙarfan yanayi da ƙarancin ciki na sassan SLS na iya buƙatar aiwatarwa bayan aiki idan ana so mai santsi ko ruwa.

4.Karshen magana

JS Additive's SLS/MJF fasahar bugu na sabis ya dogara ne akan kayan HP nailan waɗanda aka saba amfani da su a kasuwa -Fari/Grey/Baki PA12 da MJF PA12 da PA12GB, kuma abokan ciniki sun san su a cikin ƙasashe daban-daban na ketare don babban inganci.

Mai ba da gudummawa:Nina