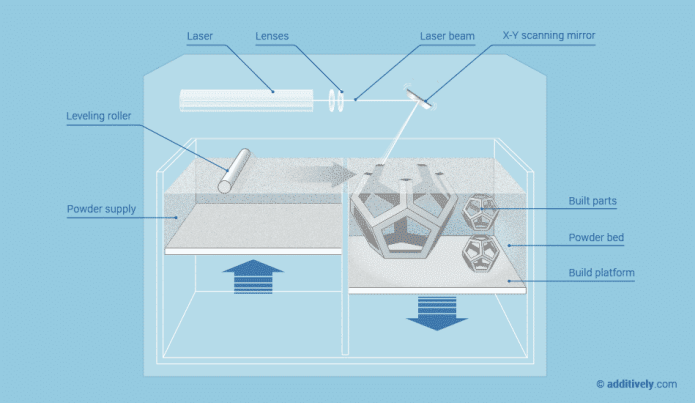

Xaiv Laser Sintering (SLS)yog lub zog 3D luam ntawv thev naus laus zis uas belongs rau cov hmoov txaj fusion txheej txheem tsev neeg uas tuaj yeem tsim cov khoom muaj tseeb thiab ruaj khov uas tuaj yeem siv ncaj qha rau kev siv kawg, cov khoom me me lossis cov qauv qauv.Thaum lub sij hawm SLS tshuab luam ntawv txheej txheem, cov khoom me me ntawm cov hmoov yas yog yaj rau hauv cov duab peb sab uas xav tau siv lub zog laser.Lub laser xaiv fuses hmoovcov ntaub ntawvlos ntawm kev txheeb xyuas cov ntaub ntawv peb-dimensional ntawm qhov chaw ntawm cov hmoov txaj.Tom qab kuaj xyuas txhua ntu ntu, cov hmoov txaj yog txo qis los ntawm ib txheej ntawm cov tuab, ib txheej tshiab ntawm cov khoom ntxiv rau nws, thiab cov txheej txheem xaiv laser sintering yog rov ua dua kom txog rau thaum cov khoom tiav.

SLS 3D luam ntawvtuaj yeem siv ob qho tib si rau kev tsim cov khoom siv ua haujlwm polymer thiab rau me mentau lawm khiavvim nws cov qib siab ntawm kev tsim kev ywj pheej, siab precision, thiab kev tsim cov khoom nrog cov khoom zoo thiab zoo ib yam.Raws li cov duab hauv qab no qhia tau hais tias:

1. Txheej txheem luam ntawv

1. Txheej txheem luam ntawv

① Ua ntej, lub silo thiab thaj chaw tsim yog rhuab kom ze rau lub melting kub ntawm lubkhoom, thiab ib txheej ntawm hmoov khoom yog pw.

② Ib lub laser yog siv los luam theej hla ntu ntawm txheej txheej no, nce qhov kub ntawm cov hmoov mus rau qhov melting point, thiab xaiv sinter lub cheeb tsam yuav tsum tau luam tawm los ua ib daim ntawv cog lus.

③ Tom qab sintering, tsim platform txav mus, lub scraper yog coated nrog lwm txheej ntawm hmoov, thiab cov ntsiab lus ntawm kauj ruam ob yog rov qab mus txog rau thaum tag nrho cov qauv yog tsim.

④ Thiab tom qab ntawv luam tawm, cov txheej txheem ua kom txias (feem ntau qis dua 40 degrees), thiab tuaj yeem pib tshem tawm cov khoom rau kev ua haujlwm tom ntej.

2. Nta

Lub ntsiab kom zoo dua ntawm SLSyog tias nws tsis xav tau kev txhawb nqa.Cov hmoov unsintered muab tag nrho cov tsim nyog kev txhawb nqa rau ib feem.Yog li ntawd, SLS tuaj yeem siv los tsim cov duab geometric dawb, tsuav yog nws tsis nyob hauv cov txheej txheem luam ntawv, cov neeg tsim qauv siv tau lawv cov txuj ci raws li lawv xav tau, yam tsis muaj kev txhawj xeeb txog kev tsim khoom.

Thaum luam ntawv nrog SLS, tshwj xeeb tshaj yog rau me me batch ntau lawm, nws yog ib qho tseem ceeb uas yuav tsum tau ua ntau tshaj ntawm tag nrho cov tsim ntim thiab ua rau kom cov luam tawm hneev taw (qhov ntim piv ntawm cov khoom luam tawm nyob rau hauv tag nrho cov luam ntawv).Tom qab txiav txim siab qhov siab tshaj plaws luam tawm raws li cov kev xav tau ntawm cov khoom luam tawm, nws yuav siv sijhawm kwv yees li tib lub sijhawm los luam tawm, tsis hais tus naj npawb ntawm cov khoom luam tawm hauv kev tswj kev luam tawm.Qhov no yog vim qhov kev sib kis ceev ntawm txhua txheej txiav txim siab tag nrho cov sij hawm luam ntawv (laser scanning tshwm sim sai heev), thiab lub tshuab yuav tsum tau voj voog los ntawm tib cov txheej txheem.

Yog li ntawd, rau lub Hoobkas uas muabSLStxheej txheem 3D luam ntawv cov kev pabcuam, nws tuaj yeem siv ntau qhov kev txiav txim, thiab ua kom zoo rau kev sib xyaw ntawm cov khoom xaj kom ntau li ntau tau hauv tib lub tsev luam ntawv rau kev tsim khoom, uas yuav txo tau cov nqi luam ntawv thiab ua kom nrawm nrawm dua.(Txo lub sijhawm tos rau kev txiav txim thiab txiav txim siab, thiab pib ua haujlwm sai).

3. Kev xav txog kev tsim teeb pom kev zoo

Vim SLS tsis xav tau cov ntaub ntawv txhawb nqa, qhov chaw nrog hollow seem tuaj yeem luam tau yooj yim thiab raug.

Qhov hollow qhov txo qhov hnyav thiab tus nqi ntawm ib feem vim tias cov khoom siv tsawg dua, uas yog qhov tseem ceeb tshwj xeeb hauv aerospace.Yog li ntawd, thaum lub sij hawm tsim ntawm ib feem, los yog thaum lub sij hawm ua cov ntaub ntawv ua ntej luam ntawv, nws yog ib qhov tsim nyog los xav txog qhov khiav tawm ntawm cov hmoov kom tshem tawm cov unsintered hmoov los ntawm sab hauv ntawm cov khoom (uas plays lub luag hauj lwm txhawb nyob rau hauv lub sintering txheej txheem. ).Nws raug nquahu kom ntxiv yam tsawg kawg 2 qhov tsawg kawg nkaus 5 hli txoj kab uas hla khiav qhov rau koj qhov tsim.

Yog tias yuav tsum tau ua kom nruj dua, qhov yuav tsum tau luam tawm tag nrho.Lwm qhov kev xaiv yog ua kom lub hollow tsim, tshem tawm qhov khiav tawm.Txoj kev no, cov hmoov ntim nruj nreem yuav raug daig rau hauv ib feem, ua kom nws cov huab hwm coj ntau ntxiv thiab muab qee qhov kev txhawb nqa ntxiv rau cov khoom siv kho tshuab tsis cuam tshuam rau lub sijhawm tsim.Internal honeycomb grid qauv tuaj yeem muab ntxiv rau lub hollow sab hauv kom ntxiv dag zog ntawm cov khoom.

4.Qhov zoo thiab qhov txwv

a) Cov txiaj ntsig tseem ceeb

b) SLS qhov chaw muaj cov khoom siv isotropic zoo, ua rau lawv zoo tagnrho rau cov khoom siv thiab cov qauv.

c) SLS tsis tas yuav muaj kev txhawb nqa thiab tuaj yeem tsim cov qauv tsim nrog cov geometry nyuaj.

d) Kev tsim muaj peev xwm ntawmSLSyog zoo tagnrho rau me me thiab nruab nrab batch ntau lawm.

② Lub ntsiab tsis zoo:

a) Qhov chaw roughness thiab sab hauv porosity ntawm SLS qhov chaw yuav xav tau tom qab ua tiav yog tias xav tau ib qho chaw du lossis dej nruj.

b) Qhov chaw roughness thiab sab hauv porosity ntawm SLS qhov chaw yuav xav tau tom qab ua tiav yog tias xav tau ib qho chaw du lossis dej nruj.

4.End lo lus

JS Additive's SLS/MJF luam ntawv thev naus laus zis kev pabcuam yog raws li cov ntaub ntawv nylon HP uas feem ntau siv hauv khw -Dawb / Grey / Dub PA12 thiab MJF PA12 thiab PA12GB, thiab tau lees paub los ntawm cov neeg siv khoom hauv ntau lub teb chaws txawv teb chaws kom zoo.

Pab txhawb nqa:Nina