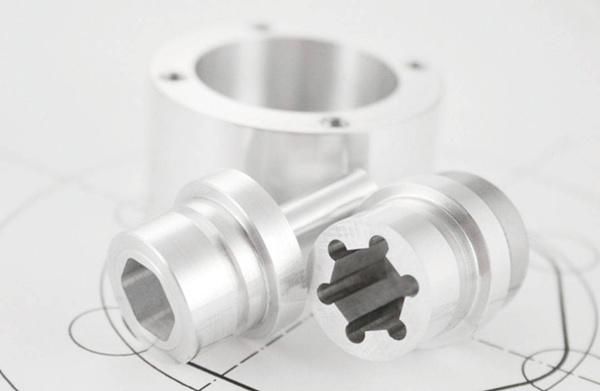

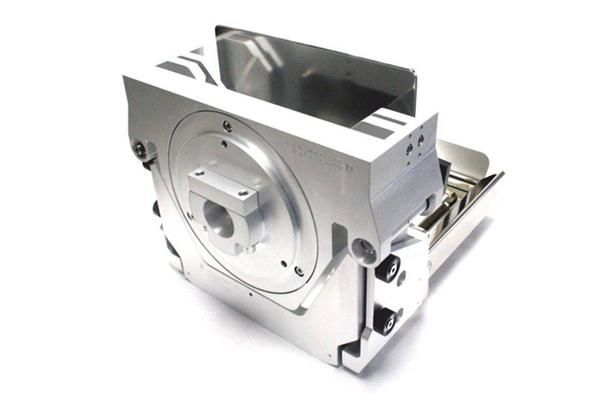

CNC ua feem ntau yog hais txog lub computer digital tswj precision machining, CNC ua tshuab dhos, CNC ua milling tshuab, CNC machining tho txawv thiab milling tshuab, thiab lwm yam.

Ntxiv rau kev muab kev pabcuam 3D luam ntawv rau cov neeg siv, nws tseem tuaj yeem muab laser txiav, silicone compound molding, thiab CNC ua thiab lwm yam kev pabcuam, ntawm cov khoom siv hlau tseem ceeb rau CNC ua cov hauv qab no:

1, aluminium alloy 6061

6061 aluminium alloy yog cov khoom zoo aluminium alloy khoom tsim los ntawm kev kho cua sov ua ntej-stretching txheej txheem.Txawm hais tias nws lub zog tsis yog piv nrog 2XXX series lossis 7XXX series, nws muaj cov yam ntxwv ntawm magnesium thiab silicon alloy ntau dua.

Khoom zoo:

Nws muaj kev ua tau zoo heev, zoo heev vuam cov yam ntxwv thiab electroplating, zoo corrosion kuj, siab toughness thiab tsis deformation tom qab ua, cov khoom ceev tsis muaj qhov tsis xws luag thiab yooj yim polishing, yooj yim xim zaj duab xis, zoo heev oxidation nyhuv thiab lwm yam zoo heev yam ntxwv.

2,7075 aluminium alloy

7075 Aluminium alloy yog ib hom kev kho mob txias forging alloy, siab zog, deb zoo dua li cov hlau mos.7075 yog ib qho ntawm cov khoom lag luam muaj zog tshaj plaws.

Khoom zoo:

Common corrosion kuj, zoo mechanical zog thiab anode cov tshuaj tiv thaiv.Cov nplej zoo ua kom sib sib zog nqus qhov kev ua haujlwm zoo dua, cov cuab yeej hnav tsis kam txhim kho, thiab xov dov ntau qhov txawv.

3. Tooj

Ntshiab tooj liab (tseem hu ua tooj liab) yog cov hlau tawv uas muaj kev ua tau zoo heev hauv Rose liab.Nws tsis yog tooj liab dawb huv, nws muaj 99.9% tooj liab, thiab ntxiv qee cov ntsiab lus los txhim kho qhov chaw thiab kev ua haujlwm.

Khoom zoo:

Nws muaj hluav taws xob zoo conductivity, thermal conductivity, ductility, sib sib zog nqus cuam tshuam thiab corrosion kuj.

Cov hluav taws xob conductivity thiab thermal conductivity ntawm ntshav tooj liab yog thib ob tsuas yog nyiaj, uas yog siv dav hauv kev tsim cov khoom siv hluav taws xob thiab thermal conductivity.Tooj liab muaj corrosion kuj zoo nyob rau hauv cov huab cua, dej hiav txwv thiab ib co tsis-oxidizing acid (hydrochloric acid, dilute sulfuric acid), alkali, ntsev tov thiab ntau yam organic acids (acetic acid, citric acid), thiab yog siv nyob rau hauv kev lag luam tshuaj. .

Zoo weldability, tuaj yeem txias, thermoplastic ua rau ntau yam khoom siv thiab cov khoom tiav.Nyob rau xyoo 1970, cov khoom siv tooj liab liab tau tshaj tawm tag nrho cov khoom siv tooj liab.

4. tooj dag

tooj dag yog tooj liab thiab zinc alloy, thiab tooj dag uas muaj tooj liab thiab zinc hu ua tooj dag zoo tib yam.

Khoom zoo:

Nws muaj lub zog siab, siab hardness thiab muaj zog tshuaj corrosion kuj.Mechanical kev ua tau zoo ntawm kev ua haujlwm yog qhov zoo tshaj plaws.

Brass muaj zog hnav-tiv taus.Cov tooj dag tshwj xeeb, tseem hu ua tooj dag tshwj xeeb, muaj lub zog siab, siab hardness thiab muaj zog tshuaj corrosion kuj.Mechanical kev ua tau zoo ntawm kev ua haujlwm yog qhov zoo tshaj plaws.Seamless tooj liab raj rub los ntawm tooj dag yog mos thiab muaj zog hnav tsis kam.

5.45 steel

45 Hlau yog lub npe ntawm GB, tseem hu ua "roj steel", cov hlau muaj lub zog ntau dua thiab kev ua haujlwm zoo dua.

Khoom zoo:

Nrog lub zog siab thiab kev txiav zoo thiab ua tiav, tom qab kev kho cua sov tsim nyog tuaj yeem tau txais qee yam tawv, plasticity thiab hnav tsis kam, cov khoom siv yooj yim, tsim rau hydrogen vuam thiab argon arc vuam.

6.40 Cr steel qhia

40 Cr yog tus qauv steel naj npawb ntawm GB hauv Suav teb, thiab 40 Cr steel yog ib qho ntawm cov hlau siv dav tshaj plaws hauv kev tsim khoom siv tshuab.

Khoom zoo:

Cov cuab yeej zoo txhua yam, zoo kub tsis tshua muaj kev cuam tshuam toughness thiab tsis tshua muaj siab rhiab heev.Hlau muaj quenability zoo, uas yog tsim rau cyanide thiab siab zaus quenching kev kho mob ntxiv rau kev kho kom zoo.Kev ua haujlwm txiav yog qhov zoo dua.

7.Q235 steel kev taw qhia

Q235 steel yog cov qauv carbon steel, thiab Q hauv nws tus lej steel sawv cev rau lub zog tawm los.Feem ntau, cov hlau yog siv ncaj qha yam tsis muaj kev kho cua sov.

Khoom zoo:

Nrog rau qhov nce ntawm cov thickness ntawm cov khoom, tus nqi tawm los yuav raug txo, vim yog cov ntsiab lus ntawm cov pa roj carbon monoxide, qhov kev ua tau zoo yog qhov zoo, lub zog, plasticity thiab vuam cov khoom zoo sib xws, feem ntau siv.

8.SUS304 hlau

SUS304 Hais txog 304 stainless hlau, nrog kev ua haujlwm zoo, cov yam ntxwv siab tawv, stainless hlau 303 kuj tuaj yeem ua tiav.

Khoom zoo:

Zoo corrosion kuj, tshav kub tsis kam, corrosion kuj, tsis tshua muaj kub lub zog thiab txhua yam khoom, zoo stamping thiab dabtsi yog khoov ntawm thermal ua, tsis muaj tshav kub kho hardening tshwm sim, tsis muaj hlau nplaum.