Electron Beam Melting(EBM)

Electron Beam Selective Melting (EBSM) Principle

Zvakafanana nelaser selective sintering uyeSarudza Laser Meltingmaitiro, electron beam selective melting tekinoroji (EBSM) inokurumidza kugadzira tekinoroji inoshandisa yakakwirira-simba uye inomhanya-mhanya matanda erekitironi kusarudza bombard simbi poda, nekudaro kunyunguduka nekugadzira hupfu.

Maitiro eEBSM tekinoroji yakaita seiyi: kutanga, paradzira chidimbu chehupfu pane ndege inoparadzira hupfu;zvino, pasi pekutonga kwekombuta, danda reerekitironi rinonyungudutswa zvinoenderana neruzivo rwemuchinjiko-chikamu, uye hupfu hwesimbi hunonyungudutswa pamwe chete, hwakabatana nechikamu chakaumbwa pazasi, uye murwi wedhiri nejira kusvikira chikamu chose chazara. melted;Pakupedzisira, hupfu hwakawandisa hunobviswa kuti ubudise chinodiwa-mativi matatu-dimensional chigadzirwa.Iyo chaiyo-nguva yekutarisisa chiratidzo chemukombuta wepamusoro inoendeswa kune yakatsauka joko mushure mekushandurwa kwedhijitari-kune-analog uye kukwidziridzwa kwesimba, uye danda re electron rinodzoserwa pasi pechiito chemagnetic field inogadzirwa neinowirirana deflection voltage kuti iwane kunyungudika kwakasarudzika. .Mushure memakore anopfuura gumi ekutsvagisa, zvinoonekwa kuti mamwe maparamita ekuita senge erekitironi danda razvino, rinotarisa zvazvino, nguva yekuita, hupfu hwehupfu, kumhanyisa voltage, uye kuvheneka maitiro anoitwa mune orthogonal kuyedza.Nguva yekuita ine simba guru pakuumba.

Zvakanakiraye EBSM

Electron danda rakananga simbi yekugadzira tekinoroji inoshandisa yakakwirira-simba erekitironi matanda seyekugadzirisa kupisa sosi.Kugadzira kuumba kunogona kuitwa pasina mechanical inertia nekushandisa magineti deflection coil, uye nzvimbo yekuvhaira ye electron beam inogonawo kudzivirira hupfu hwesimbi kuti huve oxidized panguva yekunyungudika kwemvura.Kuenzaniswa nelaser, erekitironi danda rine mabhenefiti eiyo yakakwira simba rekushandisa chiyero, yakakura chiito kudzika, yakakwirira yekunyudza zvinhu, kugadzikana uye kuderera kwekushanda uye mutengo wekugadzirisa.Mabhenefiti eEBM tekinoroji anosanganisira yakakwira kuumba kunyatsoita, yakaderera chikamu deformation, hapana chikonzero chekutsigirwa nesimbi panguva yekugadzira maitiro, denser microstructure, zvichingodaro.Iyo electron beam deflection uye kutarisa kwekutarisa kunokurumidza uye kwakanyanya kunzwa.Kutsauka kwelaser kunoda kushandiswa kwegirazi rinozunguza, uye girazi rinotenderera rinotenderera rinomhanya zvakanyanya kana laser inotarisa nekumhanya kwakanyanya.Kana iyo laser simba ichiwedzerwa, iyo galvanometer inoda yakaoma kutonhora system, uye uremu hwayo hunowedzera zvakanyanya.Nekuda kweizvozvo, kana uchishandisa yakakwirira simba scanning, iyo laser's scanning kumhanya ichave shoma.Paunenge uchitarisa yakakura yekugadzira renji, kushandura iyo yakatarisa kureba kwelaser zvakare kwakaoma.Iko kutsauka uye kutarisa kweyerekitironi danda kunoitwa nemagineti.Kutsauka uye kutarisisa kureba kweyerekitironi danda kunogona kudzorwa nekukurumidza uye nekunzwa nekushandura kusimba uye kwakanangana nechiratidzo chemagetsi.Iyo erekitironi danda deflection inotarisa sisitimu haizokanganiswe nesimbi evaporation.Pakunyungudusa simbi ine lasers uye matanda erekitironi, mhute yesimbi inopararira munzvimbo yese yekugadzira uye kupfekedza pamusoro pechinhu chero chipi zvacho chakasangana nefirimu resimbi.Kutsauswa uye kutarisisa kwemaerekitironi matanda ese anoitwa mune remagineti, saka haazokanganiswe nekubuda kwesimbi;Optical zvishandiso senge laser galvanometers zviri nyore kusvibiswa nekubuda.

Laser Metal Deposition(LMD)

Laser Metal Deposition (LMD) yakatanga kukurudzirwa neSandia National Laboratory muUnited States muma1990s, ndokuzogadziridzwa zvakatevedzana munzvimbo zhinji dzepasi.Sezvo mayunivhesiti mazhinji nemasangano anoita tsvakiridzo akazvimirira, tekinoroji iyi Kune mazita mazhinji, kunyangwe mazita asina kufanana, asi misimboti yavo yakafanana.Munguva yekugadzira, hupfu hunounganidzwa mundege yekushanda kuburikidza nemuromo, uye laser beam inounganidzwawo kusvika panguva ino, uye hupfu uye chiedza chekuita mapoinzi zvinosangana, uye iyo yakaturikidzana yakavharidzirwa inowanikwa nekufamba nepakati pebasa rekushanda. kana muromo.

LENS tekinoroji inoshandisa kilowatt-kirasi lasers.Nekuda kweiyo hombe yekutarisa laser nzvimbo, kazhinji inodarika 1mm, kunyangwe simbi yakasungirirwa simbi yakakora inogona kuwanikwa, kurongeka kwavo kwedimensional uye kupera kwepasi hakuna kunyatso kunaka, uye kuwedzera machining kunodiwa usati washandiswa.Laser cladding yakaoma yemuviri uye yemakemikari metallurgical process, uye maparamita eiyo cladding process ane simba guru pamhando yeakapfekwa zvikamu.Iwo maitiro maparamendi mune laser cladding anonyanya kusanganisira laser simba, nzvimbo dhayamita, defocusing huwandu, hupfu hwekudyisa kumhanya, scanning kumhanya, yakanyungudutswa yedziva tembiricha, nezvimwewo, izvo zvine simba guru pachiyero che dilution, kutsemuka, kushata kwepamusoro uye kuumbwa kwezvikamu zvekupfeka. .Panguva imwecheteyo, imwe neimwe parameter inobatawo kune imwe neimwe, iyo yakaoma zvikuru.Nzira dzakakodzera dzekudzora dzinofanirwa kugamuchirwa kudzora dzakasiyana-siyana zvinofurira zvinhu mukati meiyo inotenderwa siyana yekupfeka maitiro.

DirectMetal Laser Sintering(DMLS)

Kazhinji pane nzira mbiri dzeSLSkugadzira zvikamu zvesimbi, imwe ndiyo nzira isina kunanga, kureva, SLS yepolymer-yakavharwa simbi poda;imwe yacho yakananga nzira, kureva, Direct Metal Laser Sintering (DMLS) .Sezvo tsvakurudzo pamusoro yakananga Laser sintering upfu simbi yakaitwa paChatofci University muLeuvne muna 1991, zvakananga sintering simbi upfu kuita matatu-dimensional zvikamu. neSLS maitiro ndechimwe chekupedzisira zvinangwa zvekukurumidza prototyping.Kuenzaniswa nesina kunanga SLS tekinoroji, mukana mukuru weDMLS maitiro ndiko kubviswa kweanodhura uye anotora nguva-ekutanga kurapwa uye mushure mekurapa maitiro matanho.

Features yeDMLS

Sebazi rehunyanzvi hweSLS, tekinoroji yeDMLS ine musimboti wakafanana.Nekudaro, zvakaoma kunyatso kuumba simbi zvikamu zvine maumbirwo akaoma neDMLS tekinoroji.Mukuongorora kwekupedzisira, inonyanya kukonzerwa ne "spheroidization" mhedzisiro uye sintering deformation yesimbi poda muDMLS.Spheroidization chiitiko umo chimiro chepamusoro chesimbi yakanyungudutswa chinoshanduka kuita chitenderedzwa pasi pekukakavadzana pakati pesimbi yemvura uye yepakati yakatenderedza kuitira kugadzira iyo system inoumbwa nepamusoro pemvura yakanyungudutswa yesimbi uye pamusoro pe. svikiro rakatenderedza rine simba shoma remahara.Spheroidization ichaita kuti simbi yehupfu isakwanise kusimba mushure mekunyunguduka kuti iite dziva rinoramba riripo uye rakatsetseka rakanyungudutswa, saka zvikamu zvakaumbwa zvakasununguka uye zvine porous, zvichiita kuti kuumbwa kukundikana.Nekuda kweiyo yakakwira viscosity ye-single-component metal poda muchikamu chemvura sintering, iyo "spheroidization" mhedzisiro yakanyanya kukomba, uye dhayamita ye spherical inowanzo hukuru kupfuura dhayamita yehupfu hwehupfu, hunotungamira kune huwandu hukuru. pores muzvikamu zvakasvibiswa.Nokudaro, iyo DMLS ye-single-component metal powder ine maitiro akaremara akajeka, uye kazhinji inoda kurapwa kunotevera, kwete pfungwa chaiyo ye "direct sintering".

Kuti ukunde "spheroidization" chiitiko cheimwe chikamu chesimbi poda DMLS uye zvinokonzeresa maitiro akaremara senge sintering deformation uye loose density, inogona kuwanikwa kazhinji kuburikidza nekushandisa akawanda-chikamu simbi hupfu dzine akasiyana mapoidhi ekunyunguduka kana kushandisa pre-alloying poda. .Iyo yakawanda-chikamu simbi poda system inowanzo umbwa nepamusoro simbi inonyungudika, yakaderera kunyungudika simbi uye zvimwe zvakawedzerwa zvinhu.Iyo yakakwirira yakanyungudika simbi poda sezvo skeleton simbi inogona kuchengetedza iyo yakasimba musimboti muDMLS.Iyo yakaderera-inonyungudika nzvimbo yesimbi hupfu inoshandiswa sesimbi inosunga, iyo yakanyungudutswa muDMLS kuita chikamu chemvura, uye inokonzeresa mvura chikamu mabhachi, inonyorovesa uye inosunga iyo yakasimba chikamu chesimbi zvimedu kuti uwane sintering densification.

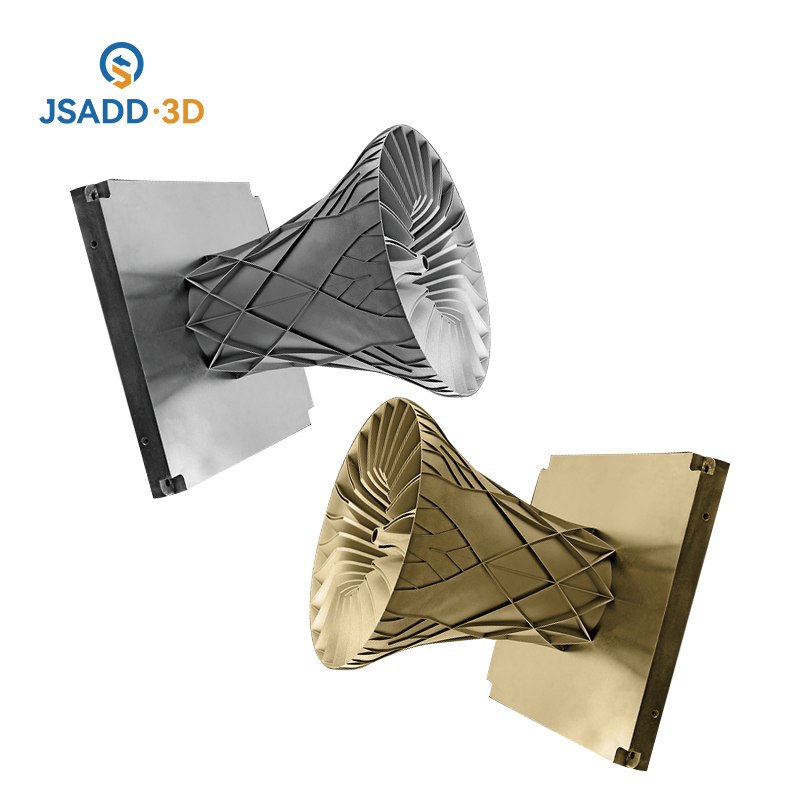

Sekambani inotungamira muChina3D kudhinda sevhisiindasitiri,JSADD3D haizokanganwe chinangwa chayo chepakutanga, wedzera mari, gadzira uye gadzira mamwe matekinoroji, uye tenda kuti ichaunza hutsva 3D kudhinda ruzivo kuruzhinji.

Mubatsiri: Sammi