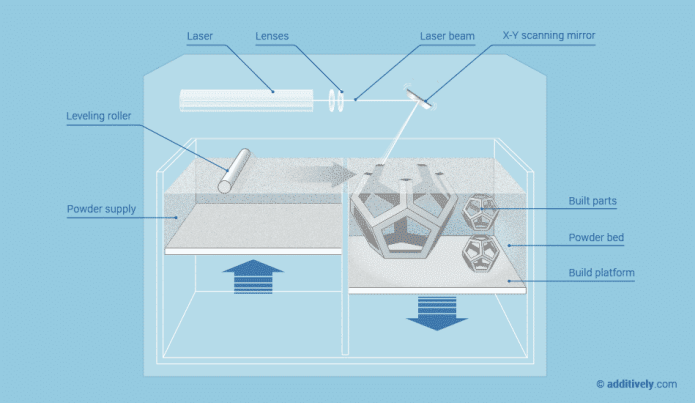

Sarudza Laser Sintering (SLS)ndiyo ine simba 3D yekudhinda tekinoroji inova yehupfu mubhedha fusion process yemhuri iyo inogona kuburitsa yakakwirira-chaiyo uye yakasimba zvikamu zvinogona kushandiswa zvakananga kushandiswa kwekupedzisira, diki kugadzira batch kana prototype zvikamu.Munguva yekudhinda mudziyo weSLS, zvidimbu zvidiki zvehupfu hwepurasitiki zvinonyungudutswa mune inodiwa matatu-dimensional chimiro uchishandisa yakakwirira-simba laser.Iyo laser inosarudza fuses podazvinhunekuongorora chikamu chetatu-dimensional data chepamusoro pemubhedha wehupfu.Mushure mekutarisa chikamu chega chega, mubhedha wehupfu unodzikiswa nechikamu chimwe cheukobvu, hutsva hwezvinhu hunowedzerwa kwairi, uye iyo yakasarudzika laser sintering process inodzokororwa kusvika chikamu chapera.

SLS 3D kudhindainogona kushandiswa zvese prototyping inoshanda polymer zvikamu uye zvedikikugadzirwa kunomhanyanekuda kwehukuru hwayo hwemhando yerusununguko rwekugadzira, kurongeka kwepamusoro, uye kugadzirwa kwezvikamu zvine yakanaka uye inopindirana ma mechanical properties.Sezvinoratidzwa nemufananidzo unotevera:

1.Printing Process

1.Printing Process

① Chekutanga, iyo silo nenzvimbo yekuvaka inodziya kuti ivhare kunyungudika tembiricha yezvinhu, uye hupfu hwehupfu hunoiswa.

② Laser inobva yashandiswa kuongorora muchinjiko-chikamu cheiyi layer, kusimudza tembiricha yehupfu kusvika painonyungudika, uye nekusarudza sinter nzvimbo ichadhindwa kuti iite chisungo.

③ Mushure mekunyungudika, chikuva chekuvaka chinodzika pasi, scraper yakaputirwa neimwe nhurikidzwa yehupfu, uye zviri mudanho rechipiri zvinodzokororwa kusvikira modhi yese yaumbwa.

④ Uye mushure mekudhinda, imba yekugadzira inotonhora pasi (kazhinji pasi pe40 degrees), uye inogona kutanga kubvisa zvikamu zvekugadzirisa zvinotevera.

2. Zvimiro

Kubatsira kukuru kweSLSndeyekuti haidi chimiro chekutsigira.Upfu husina kuiswa hunopa hutsigiro hunodiwa hwechikamu.Nokudaro, SLS inogona kushandiswa kugadzira mahara ejometri maumbirwo, chero bedzi iri mukati memiganhu yekudhinda, vagadziri vanogona kushandisa matarenda avo sezvavanoda, pasina kunetseka nezvekugadzira.

Paunenge uchidhinda neSLS, kunyanya pakugadzirwa kwebatch diki, zvakakosha kuti ushandise zvakanyanya vhoriyamu yese yekuvaka uye kuwedzera print footprint (chiyero chevhoriyamu yechigadzirwa chakadhindwa mubhini rese rekudhinda).Mushure mekuona hurefu hwakanyanya hwekudhindwa zvichienderana nehurongwa hwezvinodiwa zvezvigadzirwa zvakadhindwa, zvinotora nguva yakaenzana yenguva kudhinda, zvisinei nehuwandu hwezvigadzirwa zvakadhindwa mukudhinda control.Izvi zvinodaro nekuti kumhanya kwekupararira kwechikamu chega chega kunotarisisa iyo yakazara nguva yekudhinda (laser scanning inoitika nekukurumidza), uye muchina uchafanirwa kutenderera kuburikidza nenhamba imwechete yezvikamu.

Naizvozvo, kune fekitori inopaSLSprocess 3D kudhinda masevhisi, inogona kushandisa nhamba yakakura yeodha, uye optimize musanganiswa wezvakaodha zvigadzirwa zvakanyanya sezvinobvira mune imwecheteyo yekuchengetera dura rekugadzira, izvo zvinozoderedza zvakanyanya mutengo wekudhinda uye kuwedzera kukurumidza kudhinda.(Deredzai nguva yekumirira maodha uye kugadzira maodha, uye nekukurumidza tanga kugadzira).

3. Chiedza chekugadzira kufunga

Sezvo SLS isingadi zvinhu zvekutsigira, zvikamu zvine mhango zvikamu zvinogona kudhindwa zviri nyore uye zvakarurama.

Iyo buri chikamu chinoderedza huremu uye mutengo wechikamu nekuti zvinhu zvishoma zvinoshandiswa, izvo zvinonyanya kukosha mumhepo.Nokudaro, panguva yekugadzirwa kwechikamu, kana panguva yekugadziriswa kwedheta isati yadhindwa, zvakakosha kufunga nezvemakomba ekupukunyuka ehupfu kuti abvise poda isina kuvharwa kubva mukati mechikamu (iyo inobata basa rinotsigira mukuita sintering. )Zvinokurudzirwa kuwedzera zvishoma zvishoma 2 mm dhayamita dhayamita inopukunyuka kune maburi ako.

Kana kuoma kukuru kuchidiwa, chikamu chinofanira kudhindwa chakasimba zvachose.Imwe sarudzo ndeyekugadzira dhizaini isina hovha, uchisiya gomba rekupukunyuka.Nenzira iyi, hupfu hwakasungirirwa huchavharirwa muchikamu, huchiwedzera huwandu hwayo uye nekupa humwe tsigiro yekupokana nemichina inotakura pasina kukanganisa nguva yekuvaka.Iyo yemukati mezinga grid chimiro inogona kuwedzerwa mukati memukati kuti iwedzere kuomarara kwechikamu.

4.Advantages uye Limitations

a) Zvakanakira zvakakosha

b) Zvikamu zveSLS zvine yakanaka isotropic mechanical zvivakwa, zvichiita kuti ive yakanakira nhengo dzinoshanda uye prototypes.

c) SLS haidi chero tsigiro uye inogona kuburitsa madhizaini neakaoma geometries.

d) Kugona kugadzira kweSLSdzakanakira kugadzirwa kwebatch madiki uye epakati.

② Zvakanyanya kuipa:

a) Iko kushata kwepamusoro uye porosity yemukati yezvikamu zveSLS zvingada post-processing kana nzvimbo yakatsetseka kana kusimba kwemvura kuchidiwa.

b) Kuoma kwepamusoro uye porosity yemukati yezvikamu zveSLS zvingada post-processing kana nzvimbo yakatsetseka kana kusimba kwemvura kuchidiwa.

4.Shoko rekupedzisira

JS Additive's SLS/MJF kudhinda tekinoroji sevhisi yakavakirwa panylon HP zvinhu zvinowanzo shandiswa pamusika -White/Grey/Black PA12 uye MJF PA12 uye PA12GB, uye inozivikanwa nevatengi munyika dzakasiyana siyana dzekunze kwemhando yepamusoro.

MubatsiriNina