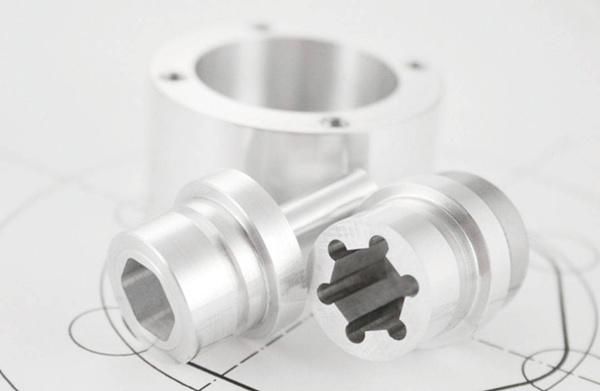

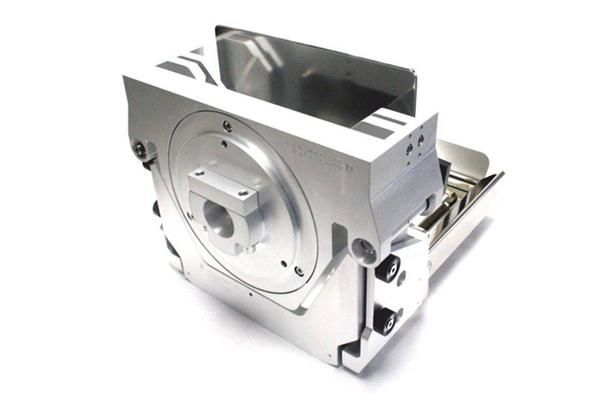

CNC kugadzirisa kazhinji inoreva komputa yedhijitari inodzora chaiyo machining, CNC kugadzirisa lathe, CNC kugadzirisa muchina wekugaya, CNC machining boring uye muchina wekugaya, nezvimwe.

Pamusoro pekupa 3D kudhinda masevhisi evashandisi, inogona zvakare kupa laser yekucheka, silicone komputa kuumbwa, uye CNC kugadzirisa uye mamwe masevhisi, pakati pawo masimbi makuru eCNC kugadzirisa ndeaya anotevera:

1, aruminiyamu chiwanikwa 6061

6061 aluminium alloy ndeyepamusoro-mhando aruminiyamu alloy chigadzirwa chinogadzirwa nekupisa kurapwa pre-kutambanudza maitiro.Kunyangwe simba rayo risingaenzaniswe ne2XXX akatevedzana kana 7XXX akatevedzana, ine yakawanda magnesium uye silicon alloy maitiro.

Zvinhu zvakanakira:

Iyo ine yakanakisa kugadzirisa mashandiro, yakanakisa welding maitiro uye electroplating, yakanaka corrosion kuramba, kusimba kwakanyanya uye hapana deformation mushure mekugadzirisa, density yezvinhu pasina kukanganisa uye kupenya kuri nyore, firimu reruvara riri nyore, yakanakisa oxidation maitiro uye humwe hunhu hwakanakisa.

2,7075 aluminium alloy

7075 Aluminium alloy imhando yemhando yekutonhora kwekugadzira alloy, kusimba kwepamusoro, kuri nani kupfuura simbi yakapfava.7075 imwe yeakanyanya simba anowanikwa mune zvekutengesa alloys.

Zvinhu zvakanakira:

Yakajairwa corrosion resistance, yakanaka ma mechanical properties uye anode reaction.Mbeu dzakatsetseka dzinoita kuti kuchera kwakadzika zviite nani, kusamira kwezvishandiso kunowedzerwa, uye shinda inomonereka zvakanyanya kusiyanisa.

3. Mhangura

Pure mhangura (inozivikanwawo semhangura) isimbi yakaoma ine conductivity yakanaka mu rose red.Haisi mhangura yakachena, ine 99.9% mhangura, uye inowedzera zvimwe zvinhu kuvandudza pamusoro uye kuita.

Zvinhu zvakanakira:

Iine yakanaka magetsi conductivity, thermal conductivity, ductility, deep impact uye corrosion resistance.

Iyo yemagetsi conductivity uye yekupisa conductivity yepepuru mhangura ndeyechipiri kune sirivheri, iyo inoshandiswa zvakanyanya mukugadzira conductive uye thermal conductivity michina.Mhangura ine yakanaka corrosion resistance mumhepo, mvura yegungwa uye imwe isiri-oxidizing acid (hydrochloric acid, dilute sulfuric acid), alkali, salt solution uye akasiyana organic acids (acetic acid, citric acid), uye inoshandiswa muindasitiri yemakemikari. .

Yakanaka weldability, inogona kutonhora, thermoplastic kugadzirisa mune akasiyana hafu-apedzwa zvigadzirwa uye zvakapedzwa zvigadzirwa.Mumakore ekuma1970, kugadzirwa kwemhangura yepepuru kwakapfuura huwandu hwemamwe marudzi ese emhangura alloys.

4.Brass

Brass imhangura uye zinc alloy, uye ndarira inoumbwa nemhangura uye zingi inonzi yakajairika ndarira.

Zvinhu zvakanakira:

Iine simba guru, kuoma kwepamusoro uye kusimba kwemakemikari e-corrosion resistance.Iyo mechanical performance yekucheka kugadzirisa zvakare yakanyanya kunaka.

Brass ine yakasimba kupfeka-resistance performance.Special brass, inozivikanwawo seyakakosha brass, ine simba rakawanda, kuomarara kwepamusoro uye yakasimba kemikari corrosion resistance.Iyo mechanical performance yekucheka kugadzirisa zvakare yakanyanya kunaka.Iyo isina musono chubhu yemhangura inodhonzwa nendarira yakapfava uye ine yakasimba kupfeka kuramba.

5.45 simbi

45 Simbi izita reGB, inonziwo "oiri simbi", simbi ine simba rakakwirira uye iri nani yekucheka kugadzirisa.

Zvinhu zvakanakira:

Nesimba rakawanda uye kucheka kwakanaka uye kugadzirisa, mushure mekupisa kwakakodzera kurapwa kunogona kuwana kumwe kuoma, plastiki uye kupfeka kuramba, zviri nyore zvinhu sosi, yakakodzera hydrogen welding uye argon arc welding.

6.40 Cr simbi sumo

40 Cr ndiyo yakajairwa nhamba yesimbi yeGB muChina, uye 40 Cr simbi ndeimwe yeanonyanya kushandiswa simbi muindasitiri yekugadzira michina.

Zvinhu zvakanakira:

Yakanaka yakazara mechanicha zvivakwa, yakanaka yakaderera-tembiricha inokanganisa kuoma uye yakaderera notch senitivity.Simbi ine yakanaka quenability, iyo inokodzera cyanide uye yakakwirira frequency quenching kurapwa mukuwedzera kune mhando kurapwa.Kuita kwekucheka kuri nani.

7.Q235 simbi sumo

Iyo Q235 simbi isimbi yekabhoni, uye iyo Q mune yayo simbi nhamba inomiririra simba regoho.Kazhinji, simbi inoshandiswa zvakananga pasina kupisa kupisa.

Zvinhu zvakanakira:

Nekuwedzera kwekukora kwezvinhu, kukosha kwegoho kuchaderedzwa, nekuda kweiyo ine mwero kabhoni yemukati, iyo yakazara mashandiro akanaka, simba, plastiki uye welding zvivakwa zviri nani kuenderana, zvakanyanya kushandiswa.

8.SUS304 Simbi

SUS304 Inoreva iyo 304 simbi isina tsvina, ine yakanaka yekugadzirisa mashandiro, yakakwirira kuomarara maitiro, Stainless simbi 303 inogona zvakare kugadziriswa.

Zvinhu zvakanakira:

Yakanaka corrosion resistance, kupisa kupisa, corrosion resistance, kuderera kwekushisa kwesimba uye michina zvivakwa, kutsika kwakanaka uye kukotama kwekupisa kwekupisa, hapana kupisa kwekupisa kuomesa chiitiko, hapana magnetism.