Hordhaca Mashiinka CNC (Birta)

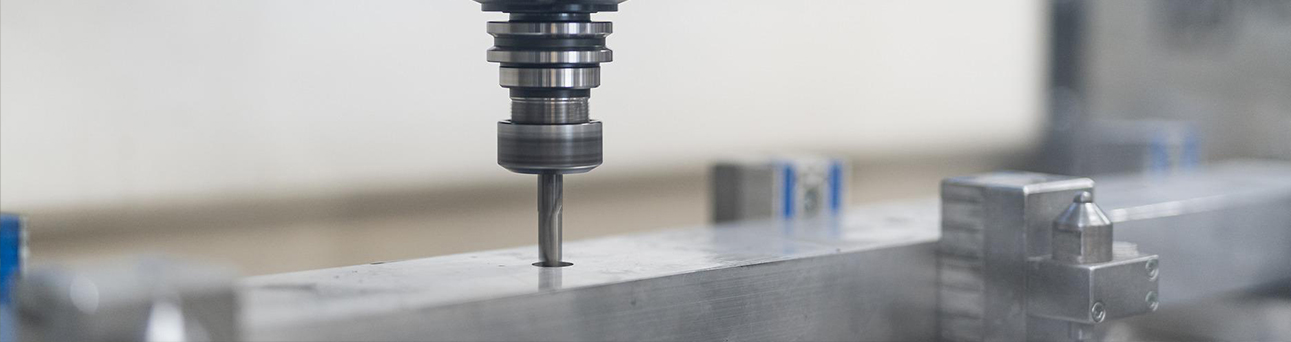

CNC Machining Metal waa isticmaalka qalabka mashiinka xakamaynta nambarada si loo farsameeyo birta iyo wixii la mid ah, sidoo kale waxaa loola jeedaa isticmaalka qalabka mashiinka xakamaynta tirooyinka.Qalabka mashiinada jibbaarada ee CNC waxaa la habeeyey oo lagu xakameeyaa luqadda kantaroolka tirooyinka, badanaa G code.Luqadda G code ee mashiinka CNC waxay u sheegaysaa isku-duwayaasha booska Kartisia ee ay adeegsato aaladda mashiinnada ee aaladaha mashiinka NC, waxayna koontaroolaysaa xawaaraha quudinta aaladda iyo xawaaraha dunta dunta, iyo sidoo kale shaqooyinka beddelka iyo qaboojiyaha.Mashiinka xakamaynta tirada ayaa faa'iidooyin weyn ka leh mashiinnada gacanta.

Waa kan sida ay u shaqeyso

Marka CNC Metal hadda la bilaabo, soo celinta asalka saddex dhidibka ah waa in la sameeyaa si loo hubiyo in saliidda tareenada hagaha iyo saliidda dunta hydraulic ee mashiinka ay ku filan yihiin.

Kuma filna in waqtigeeda lagu shubo.Cabbirka workpiece processing waa in u dhigma sawirada, xitaa haddii farqiga yar oo kaliya ayaa sidoo kale u leeyihiin in la weydiiyo maamulka sare ama barnaamijka.

Habka habaynta barnaamijku wuu jabay marka marka barnaamijku sidoo kale u nugul yahay qaladka, waa in la hubiyaa wakhtiga.dhidibka XYZ waa in meesha laga saaro isla mar ahaantaana qalabka wax laga beddelayo habaynta.

Tusaalaha habaynta guud inta badan waxa ka mid ah saxnaanta godka biinanka, godka biinanka hagaha, jeexjeexa jeexjeexa, goynta, iwm.

Si fudud u farsamaynta mindida goynta: tani waa waayo-aragnimada mashiinka qalliinka, bilawga waxaa laga yaabaa inaanay tixgelin dhinacyadan, tan iyo waayo-aragnimada waa in aan maskaxda ku haynaa in ay la kulmeen farsamaynta meel la mid ah dareenkooda.

Faa'iidooyinka

- 1.Nidaamku waa sahlan tahay in la barnaamijiyo oo soo saari kara qaybo leh joomatari fudud, oo leh saxsanaan sare.

- 2.Waxay leedahay awood-soo-saar sare.

- 3.Kharashka mashiinada qayb kasta waa mid hooseeya.

- 4.3-dhidibka CNC mashiinnada ayaa ka qaalisan kuwa dhiggooda ah ee 5-dhidibka ah.

Khasaaro

- Shuruudaha farsamada sare ee hawlwadeenada iyo shaqaalaha dayactirka mishiinka.

- Qiimaha iibka qalabka mashiinka waa qaali.

Warshadaha leh CNC Machining Metal

● ABS: Cadaan, huruud fudud, madow, casaan.● PA: Caddaan, huruud fudud, madow, buluug, cagaar.● PC: hufan, madow.● PP: Caddaan, madow.● POM: Caddaan, madow, cagaar, cawl, jaalle, casaan, buluug, oranji.

Processing ka dib

Inta badan qalabka birta ah, halkan waxaa ah farsamooyinka farsamaynta boostada oo laga heli karo JS Additive.

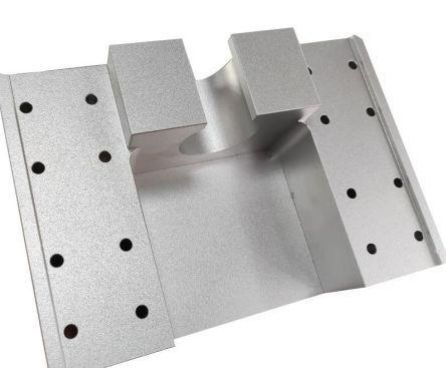

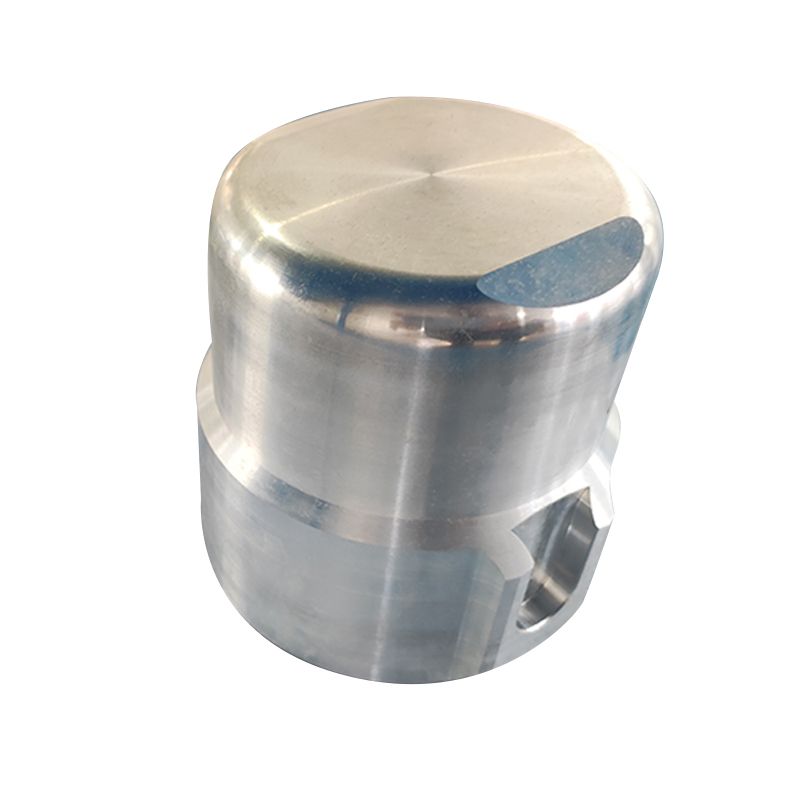

Qalabka Biraha ee CNC Machining

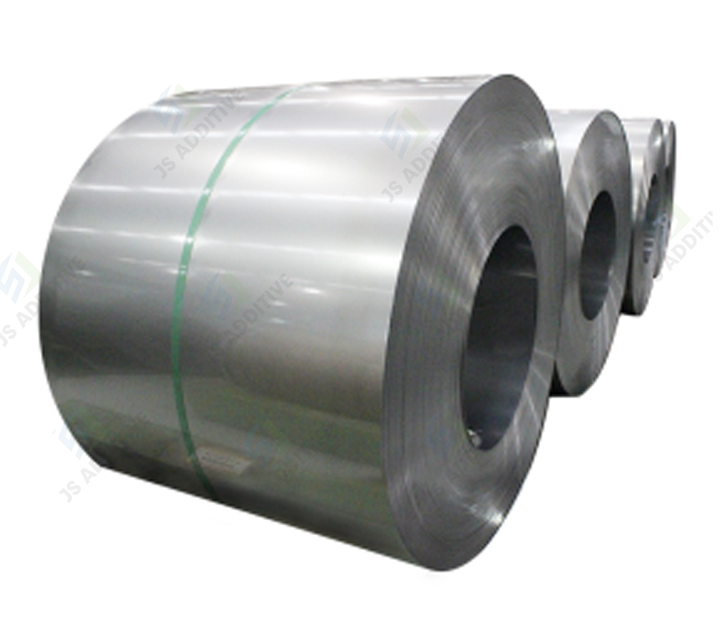

Isku-darka JS wuxuu bixiyaa CNC Machining Mashiinka Qalabka Birta: Aloyum Aluminium, Naxaas ah, S45C, Q235 Birta, Birta Sainless, Titanium Alloy, D2 Steel, Magnesium Alloy

Adeegga Farsamada Birta Mashiinka ee ugu Fiican ee laga helo JS Additive.