Hordhaca Daabacaadda 3D ee SLA

SLA-magaca buuxa waa Stereolithography Appearance, oo sidoo kale loo yaqaan Laser Rapid Prototyping.Waa tii ugu horreysay ee hababka wax-soo-saarka wax-soo-saarka ee si wadajir ah loo yaqaan "daabacaadda 3D", kaas oo ahaa habka ugu bisil uguna isticmaalka badan.ka ciyaarista door muhiim ah naqshadeynta hal-abuurka, caafimaadka ilkaha, wax-soo-saarka warshadaha, farsamada gacanta, waxbarashada kulliyadda, moodooyinka qaab dhismeedka, caaryada dahabka, habeynta shaqsiyeed iyo qeybaha kale.

SLA waa tignoolajiyada wax-soo-saarka wax-soo-saarka ee wax-soo-saarka ah oo ka shaqeysa iyadoo diiradda la saarayo laysarka ultraviolet oo dul saaran tamaar of resin photopolymer.Resin-ku waa sawir kiimiko ah oo la xoojiyay waxaana la sameeyay hal lakab oo shayga 3D ee la doonayo, habkaas oo lagu celceliyo lakab kasta ilaa qaabka la dhammeeyo.

Waa kan sida ay u shaqeyso

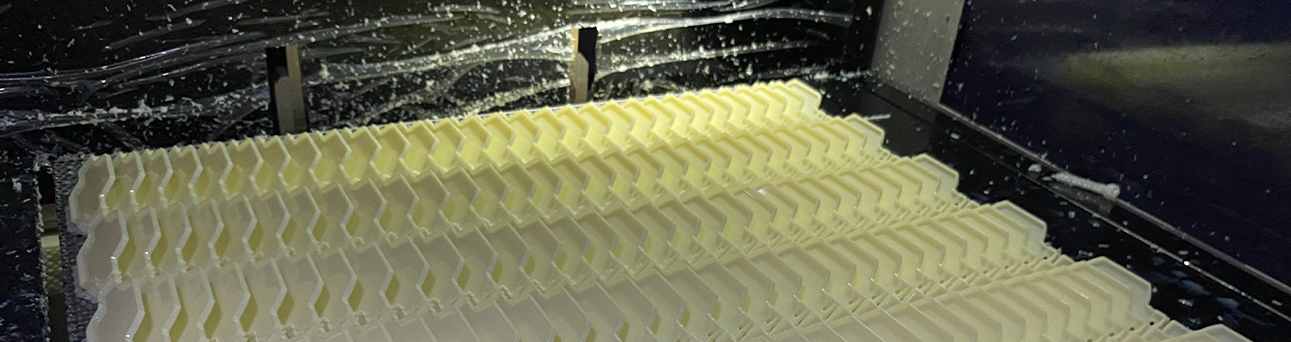

Laysarka (mawjadda dhererka la dejiyay) ayaa lagu shubay dusha sare ee resin-ka sawir-qaadista, taasoo keenaysa in resinku uu polymerizes oo uu adkeeyo min dhibic ilaa xariiq iyo xariiq ilaa dusha sare.Ka dib markii lakabka ugu horreeya la daaweeyo, goobta shaqada ee toosan waxay hoos u dhigtaa dhererka dhumucda lakabka, xoqin xoqida lakabka sare ee heerka resin, sii wad si aad u sawirto lakabka soo socda ee daaweynta, si adag isku dheji, ugu dambeyntii samee qaabka 3D ee aan rabno.

Stereolithography waxay u baahan tahay qaab-dhismeedyo taageero ah oo loogu talagalay dusha sare, kuwaas oo lagu dhisay walxo isku mid ah.Taageerada loo baahan yahay ee dusha sare iyo godadka si toos ah ayaa loo soo saarayaa, ka dibna gacanta ayaa laga saaraa.

Faa'iidooyinka

- Saxnimada sare & Faahfaahinta saxda ah: SLA waxay leedahay dulqaad ± 0.1mm.Dhumucda lakabka ugu yar ee wax soo saarka saxda ah wuxuu gaari karaa 0.05 mm

- Dusha Jilicsan: Way siman yihiin in la taabto oo si fudud loo ciid iyo rinji ama habayn kale oo kale

- Xulashada Qalabka: Qalab kala duwan ayaa loo dooran karaa iyadoo loo eegayo shuruudaha macaamilka, sida adkaanta, dabacsanaanta iyo caabbinta kulaylka.

- Qiimaha Badbaadinta: Marka la barbar dhigo CNC-dhaqameedka, SLA waxay badbaadin kartaa shaqo badan iyo kharashyo waqti.

- Si fudud u Buuxi Qaababka Weyn & Kakan: SLA wax xaddidaad ah kuma laha qaab-dhismeedka moodeelka;Madbacadaha SLA-heer warshadeed waxay dhamaystiri karaan moodooyinka 1.7 mitir ama ka sii weyn.

- Shakhsiyeynta & Daabacaadda Dhammaan-in-hal: SLA waxaa loo habeyn karaa iyadoo loo eegayo baahiyaha macaamiisha.

Khasaaro

- Qaybaha SLA inta badan waa kuwo jilicsan oo aan ku habboonayn codsiyada shaqeynaya.

- Taageerada ayaa soo muuqan doona inta lagu jiro wax soo saarka, kuwaas oo u baahan in gacanta laga saaro;Waxay ka tagi doontaa raadadka nadiifinta.

Warshadaha leh daabacaadda SLA 3D

Iyada oo in ka badan 30 sano oo horumarin ah, tignoolajiyada daabacaadda SLA 3D waxay ahayd tan ugu qaan-gaadhka ah uguna kharashka badan ee teknoolojiyadda daabacaadda 3D ee kala duwan xilligan, oo si ballaaran looga isticmaalo goobo badan oo warshado ah.Adeegga farsamaynta degdega ah ee SLA ayaa si weyn kor ugu qaaday horumarka iyo hal-abuurka warshadahan.

Processing ka dib

Maadaama moodooyinka lagu daabaco tignoolajiyada SLA, si fudud ayaa loo ciidi karaa, rinjiyeeyay, loogu dhejin karaa korantada ama shaashadda.Inta badan alaabada balaastiigga ah, halkan waxaa ah farsamooyin wax-ku-ool ah oo la heli karo.

Qalabka SLA

Daabacaadda SLA 3D, waxaan ku dhameyn karnaa wax soo saarka qaybo waaweyn oo leh saxnaan wanaagsan iyo dusha siman.Waxa jira afar nooc oo maaddooyinka resinka ah oo leh astaamo gaar ah.

| SLA | Qaabka | Nooca | Midabka | Farsamada | Dhumucda lakabka | Astaamaha |

| KS408A | ABS sida | Caddaan | SLA | 0.05-0.1mm | Dusha sare ee wanaagsan & qallafsanaanta wanaagsan |

| KS608A | ABS sida | Huruud khafiif ah | SLA | 0.05-0.1mm | Xoog sare & adayg adag |

| KS908C | ABS sida | bunni | SLA | 0.05-0.1mm | Dusha sare ee wanaagsan & geesaha iyo geesaha cad |

| KS808-BK | ABS sida | Madow | SLA | 0.05-0.1mm | Aad u saxsan oo adag |

| Somos Ledo 6060 | ABS sida | Caddaan | SLA | 0.05-0.1mm | Xoog Sare & Adag |

| Somos® Taurus | ABS sida | Dhuxul | SLA | 0.05-0.1mm | Xoog sare & adkeysi |

| Somos® GP Plus 14122 | ABS sida | Caddaan | SLA | 0.05-0.1mm | Aad u saxan oo waara |

| Somos® EvoLVe 128 | ABS sida | Caddaan | SLA | 0.05-0.1mm | Xoog sare & cimri dherer |

| KS158T | PMMA sida | Hufan | SLA | 0.05-0.1mm | Hufnaan heersare ah |

| KS198S | Rubber sida | Caddaan | SLA | 0.05-0.1mm | Dabacsanaan sare |

| KS1208H | ABS sida | Semi-translucent | SLA | 0.05-0.1mm | Cadaadiska heerkulka sare |

| Somos® 9120 | PP sida | Semi-translucent | SLA | 0.05-0.1mm | Iska caabbinta kiimikada sare |