Kaunggulan

- Fleksibilitas tinggi

- résistansi cimata alus

- Kacida akurat

- Warna bodas alus teuing

Aplikasi idéal

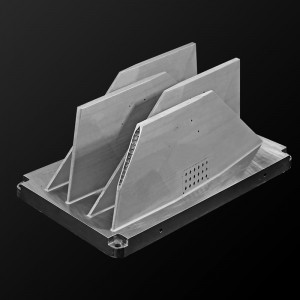

- Sapatu

- Prototipe peryogi bahan sapertos karét

- Model tampilan bodas lemes

Pasipatan cair

| Penampilan | Bodas | Dp | 13,5 mJ/cm2 | [paparan kritis] |

| Viskositas | 560 cps@30 ℃ | Js | 0,125 mm | [kemiringan cure-depth vs. In (E) curve] |

| Kapadetan | 1,1 g/cm3 | Ketebalan lapisan wangunan | 0,08-0,12 mm |

| Sipat mékanis | UV Postcure | |

| PANGUKURAN | METODE UJI | NILAI |

| Teuas, Shore D | ASTM D 2240 | 72-78 |

| Modulus lentur, Mpa | ASTM D 790 | 2.680-2.775 |

| Kakuatan lentur, Mpa | ASTM D 790 | 65-75 |

| modulus tegangan, MPa | ASTM D 638 | 2.170-2.385 |

| Kakuatan tensile, MPa | ASTM D 638 | 25-30 |

| Elongation dina putus | ASTM D 638 | 12 -20% |

| Kakuatan dampak, notched lzod, J/m | ASTM D 256 | 58 - 70 |

| Suhu defleksi panas, ℃ | ASTM D 648 @66PSI | 50-60 |

| Transisi kaca, Tg | DMA, E"puncak | 55-70 |

| Kapadetan, g/cm3 | 1.14-1.16 | |