Ukuqaliswa koMatshini we-CNC (isinyithi)

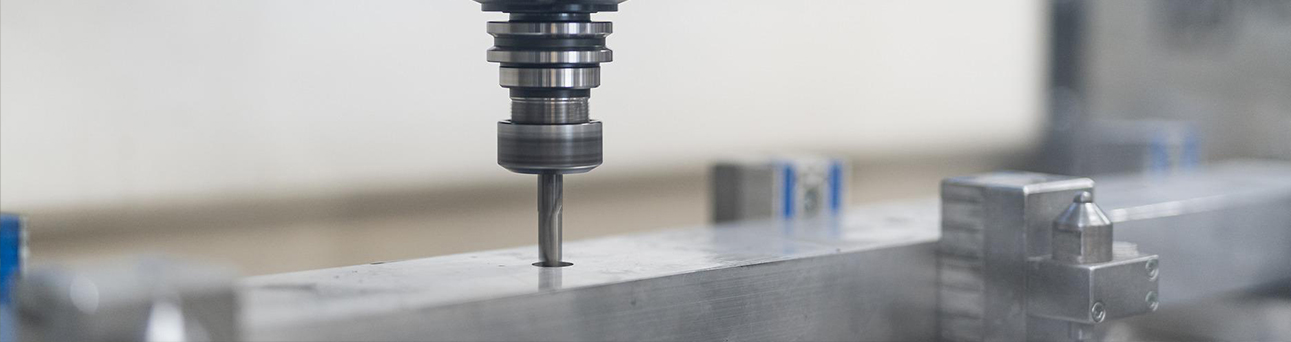

I-CNC Machining Metal kukusetyenziswa kwezixhobo zoomatshini bolawulo lwamanani ukusetyenzwa kwesinyithi njalo njalo, kukwabhekiselele ekusetyenzisweni kwezixhobo zokulawula amanani.Izixhobo zoomatshini be-CNC zicwangciswe kwaye zilawulwa ngolwimi lolawulo lwamanani, ngokuqhelekileyo ikhowudi ye-G.Ulwimi lwekhowudi ye-G ye-CNC machining ixelela ulungelelwaniso lweCartesian olusetyenziswa sisixhobo somatshini wezixhobo zomatshini we-NC, kwaye ilawula isantya sokutya kwesixhobo kunye nesantya sokujikeleza, kunye nemisebenzi yokuguqula isixhobo kunye nokupholisa.Umatshini wolawulo lwamanani uneenzuzo ezinkulu ngaphezu kokwenza ngesandla.

Nantsi indlela esebenza ngayo.

Xa i-CNC Metal isanda kuqaliswa, ukubuyiselwa kwemvelaphi ye-axis ezintathu kufuneka kuqhutywe ukujonga ukuba i-oyile yesikhokelo sikaloliwe kunye neoli ye-hydraulic spindle yomatshini yanele.

Akwanelanga ukugcwalisa kwangexesha.Ubungakanani bomsebenzi wokucubungula kufuneka buhambelane nemizobo, nokuba isithuba esincinci kuphela kufuneka sibuze ulawulo olungentla okanye inkqubo.

Kwinkqubo yokucutshungulwa kweprogram yaphukile ngoko xa inkqubo iphinda ithande impazamo, kufuneka ihlolwe ngexesha.I-axis ye-XYZ kufuneka ikhutshwe ngexesha elinye njengoko isixhobo kufuneka sitshintshwe ekuqhubeni.

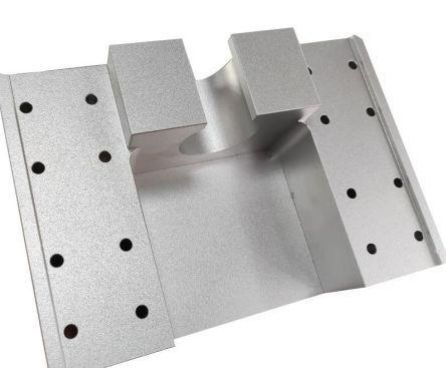

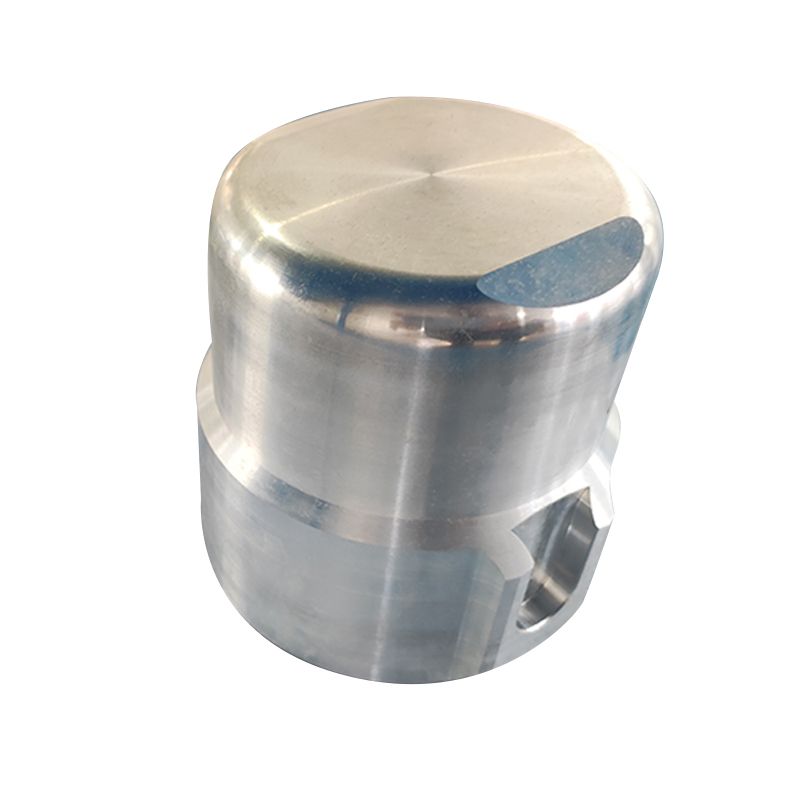

Umzekelo wokusetyenzwa ngokubanzi ikakhulu ubandakanya ukuchaneka komngxuma wephini, umngxuma wesikhonkwane sesikhokelo, faka igroove, i-slotting, njl.

Ngokulula ekuqhubeni imela yokusika: la ngamava omatshini wokusebenza, abaqalayo banokungayithatheli ngqalelo le miba, kuba amava kufuneka sikhumbule ukuba adibane nawo ekusetyenzweni kwendawo efanayo ingqalelo yabo.

Iingenelo

- I-1.Inkqubo kulula ukuyicwangcisa kwaye inokuvelisa iinxalenye ngejometri elula, ngokuchaneka okuphezulu.

- I-2.Inamandla aphezulu okuvelisa.

- 3.Iindleko zokutshiza ngenxalenye nganye ziphantsi.

- I-4.3-axis ye-CNC yokusila ayibizi kakhulu kunee-axis ezi-5.

Iingxaki

- Iimfuno eziphezulu zobugcisa kubaqhubi kunye nabasebenzi bokugcina umatshini.

- Iindleko zokuthenga izixhobo zoomatshini ziyabiza.

Amashishini aneCNC Machining Metal

● I-ABS: Emhlophe, etyheli ekhanyayo, emnyama, ebomvu.● I-PA: Emhlophe, etyheli ekhanyayo, emnyama, eluhlaza okwesibhakabhaka, eluhlaza.● I-PC: Ecacileyo, emnyama.● PP: Emhlophe, emnyama.● I-POM: Emhlophe, emnyama, eluhlaza, engwevu, emthubi, ebomvu, eblowu, eorenji.

iPost Processing

Kwiimathiriyeli ezininzi zetsimbi, nazi iindlela zokulungiswa kweposi ezifumaneka kwi-JS Additive.

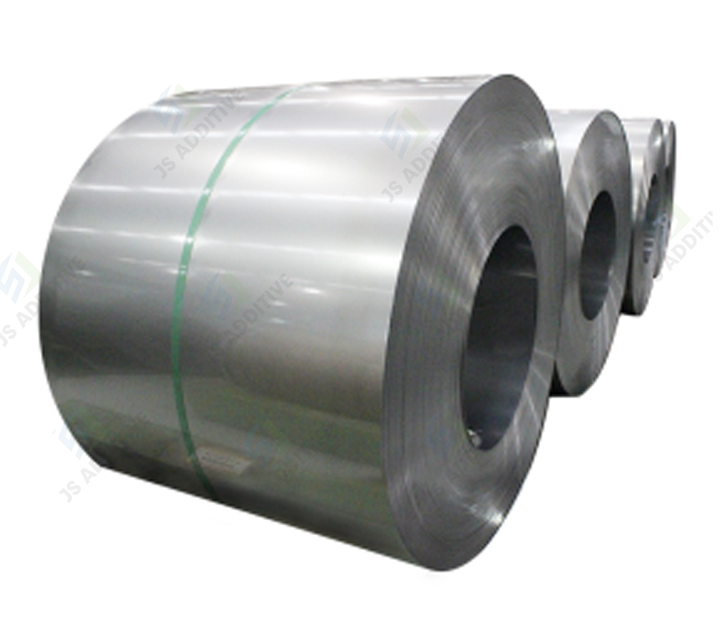

CNC Machining Metal Materials

I-JS Additive Ibonelele nge-CNC Machining Metal Materials: iAluminiyam ingxubevange, iBrass, S45C, Q235 Steel, Sainless Steel, Titanium Alloy, D2 Steel, Magnesium Alloy

Eyona Nkonzo ye-CNC yoMatshini yeMetal Technique evela kwi-JS Additive.