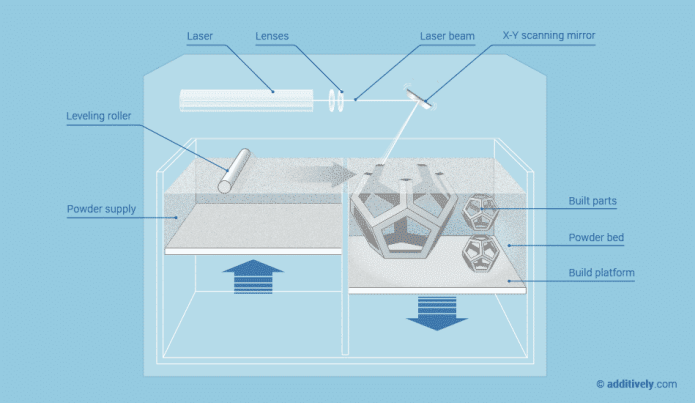

Ukukhetha iLaser Sintering (SLS)Itekhnoloji yoshicilelo ye-3D enamandla yenkqubo yosapho lwenkqubo yokudibanisa ibhedi enokuvelisa iindawo ezichanekileyo nezizinzileyo ezinokuthi zisetyenziswe ngokuthe ngqo ekusetyenzisweni kokuphela, ukuveliswa kwebhetshi encinci okanye iinxalenye zeprototype.Ngexesha lenkqubo yoshicilelo lwesixhobo se-SLS, amasuntswana amancinane omgubo weplastiki anyibilika abe bubume obunqwenelekayo obuthathu kusetyenziswa i-laser enamandla kakhulu.I-laser idibanisa umgubo ngokukhethaizixhobongokuskena icandelo ledatha lesithathu-dimensional kumphezulu webhedi engumgubo.Emva kokuskena icandelo ngalinye elinqamlezileyo, ibhedi yomgubo ithotywa ngumaleko omnye wobunzima, umaleko omtsha wezinto zongezwa kuyo, kwaye inkqubo ekhethiweyo ye-laser sintering iphinda ide igqitywe.

SLS 3D yoshicileloingasetyenziselwa zombini ukwenza iprototyping yamacandelo epholima esebenzayo kunye nakwincinciimveliso iyaqhubangenxa yenqanaba eliphezulu lenkululeko yoyilo, ukuchaneka okuphezulu, kunye nokuveliswa kwamalungu aneempawu ezilungileyo kunye nezihambelanayo zoomatshini.Njengoko umfanekiso ulandelayo ubonisa:

1. Inkqubo yoShicilelo

1. Inkqubo yoShicilelo

① Okokuqala, isisele kunye nendawo yokwakha zifudunyezwa ukuvala ubushushu bokunyibilika kweimpahla, kwaye i-layer ye-powder material ibekwe.

② I-laser ke isetyenziselwa ukuskena icandelo elinqamlezayo lomaleko, ukuphakamisa ubushushu bomgubo ukuya kwindawo yokunyibilika, kwaye ngokukhetha indawo enokuprintwa ukwenza ibhondi.

③ Emva kwe-sintering, iqonga lokwakha liyehla, i-scraper igqunywe ngolunye umaleko wezinto zomgubo, kwaye imixholo yesinyathelo sesibini iphinda iphindwe de yonke imodeli yenziwe.

④ Kwaye emva kokuprinta, igumbi lokubumba liphola phantsi (ngokubanzi ngaphantsi kwe-40 degrees), kwaye inokuqalisa ukususa iinxalenye zenkqubo elandelayo.

2. Iimpawu

Inzuzo ephambili ye-SLSkukuba ayifuni isakhiwo senkxaso.I-powder engafakwanga inika yonke inkxaso efunekayo kwinxalenye.Ngoko ke, i-SLS ingasetyenziselwa ukudala imilo yejometri yamahhala, ngokude nje ingaphakathi kweeparitha zenkqubo yokushicilela, abaqulunqi bangasebenzisa iitalente zabo njengoko benqwenela, ngaphandle kokukhathazeka malunga nokuvelisa.

Xa uprinta nge-SLS, ngakumbi kwimveliso yebhetshi encinci, kubalulekile ukwenza uninzi lwalo lonke umthamo wokwakha kunye nokwandisa ushicilelo lweenyawo (ubungakanani bomthamo wemveliso eprintiweyo kuyo yonke i-bin yokushicilela).Emva kokumisela ubude obuphezulu bokushicilela ngokusekelwe kwiimfuno zoyilo lweemveliso eziprintiweyo, kuya kuthatha malunga nexesha elifanayo lokushicilela, kungakhathaliseki ukuba inani leemveliso eziprintiweyo kulawulo loshicilelo.Oku kungenxa yokuba isantya esisasazwayo somaleko ngamnye simisela ixesha elipheleleyo loshicilelo (ukuskena ngelaser kwenzeka ngokukhawuleza okukhulu), kwaye umatshini kuya kufuneka ujikeleze inani elifanayo leeleya.

Ke ngoko, kumzi-mveliso obonelelaSLSinkqubo yeenkonzo zoshicilelo lwe-3D, inokusebenzisa inani elikhulu lee-odolo, kwaye yandise indibaniselwano yeemveliso eziyalelweyo kangangoko kunokwenzeka kwindawo yokugcina impahla yoshicilelo, eya kunciphisa kakhulu iindleko zokushicilela kunye nokwandisa isantya sokushicilela.(Nciphisa ixesha lokulinda ii-odolo kunye nokwenza imiyalelo, kwaye uqalise ngokukhawuleza ukuvelisa).

3. Iingqwalasela zoyilo olulula

Ekubeni i-SLS ayifuni izinto ezixhasayo, iinxalenye ezinamacandelo angenanto zinokushicilelwa ngokulula nangokuchanileyo.

Inxalenye engumngxuma iyanciphisa ubunzima kunye neendleko zenxalenye kuba kusetyenziswa izinto ezincinci, ezibaluleke kakhulu kwi-aerospace.Ngoko ke, ngexesha loyilo lwenxalenye, okanye ngexesha lokucutshungulwa kwedatha ngaphambi kokuprintwa, kuyimfuneko ukuqwalasela imingxuma yokuphunyuka kwepowder ukususa i powder engaxutywanga ngaphakathi kwecandelo (elidlala indima exhasayo kwinkqubo yokucoca. ).Kuyacetyiswa ukuba udibanise imingxunya emi-2 ubuncinane eyi-5 mm ebalekayo kuyilo lwakho.

Ukuba kufuneka ukuqina okukhulu, inxalenye kufuneka iprintwe yomelele ngokupheleleyo.Enye inketho kukwenza uyilo olungenanto, ukushiya umngxuma wokuphuma.Ngale ndlela, i-powder efakwe ngokuqinileyo iya kubanjiswa kwinxalenye, ikhulise ubunzima bayo kwaye inike inkxaso eyongezelelweyo ngokuchasene nemithwalo yomatshini ngaphandle kokuchaphazela ixesha lokwakha.Isakhiwo segridi ye-honeycomb yangaphakathi sinokudibaniswa kwi-interior evulekileyo ukunyusa ngakumbi ukuqina kwecandelo.

4.Izinto eziluncedo kunye neMida

a) Iinzuzo eziphambili

b) Amalungu e-SLS aneempawu ezilungileyo ze-isotropic mechanical, ezenza zilungele iindawo ezisebenzayo kunye neeprototypes.

c) I-SLS ayifuni nkxaso kwaye inokuvelisa ngokulula uyilo ngeejometri ezintsonkothileyo.

d) Ubunakho bokuvelisaSLSzilungele imveliso yebhetshi encinci naphakathi.

② Izinto ezingalunganga:

a) Uburhabaxa bomphezulu kunye ne-porosity yangaphakathi yamalungu e-SLS anokufuna emva kokulungiswa ukuba umphezulu ogudileyo okanye ukuqina kwamanzi kuyafunwa.

b) Uburhabaxa bomphezulu kunye ne-porosity yangaphakathi yamalungu e-SLS anokufuna emva kokulungiswa ukuba umphezulu ogudileyo okanye ukuqina kwamanzi kuyafunwa.

4.Igama lokugqibela

Inkonzo yeteknoloji yoshicilelo ye-JS Additive ye-SLS/MJF isekwe kwimathiriyeli yenayiloni ye-HP edla ngokusetyenziswa kwimarike –Emhlophe / eGrey / emnyama PA12 kunye ne-MJF PA12 kunye ne-PA12GB, kwaye yamkelwa ngabathengi kumazwe ahlukeneyo aphesheya komgangatho ophezulu.

Umxhasi:UNina