Inkonzo yoShicilelo ye-3D yobuNgcali

Ukuqaliswa kwe-SLM 3D Printing

I-SLM yitekhnoloji enomdla enezicelo ezininzi ezinokubakho.Njengoko iimeko zokusetyenziswa zikhula, itekhnoloji ikhula, kwaye iinkqubo kunye nemathiriyeli ibiza ixabiso eliphantsi, kufuneka siyibone iyinto eqhelekileyo, isetyenziswa ngokubanzi kwiindawo ezininzi.

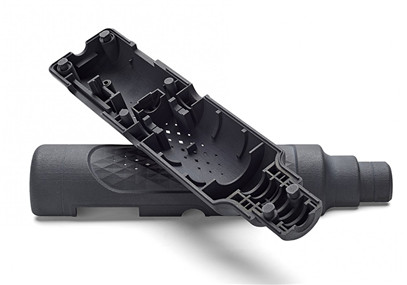

1- Yenza umaleko olandelayo womaleko womgubo ongalungiswanga, uthintele ukuskena kwelaser kungqimba olungqindilili lwesinyithi kunye nokuwa;

I-2- Emva kokuba i-powder ishushu, iyancibilika kwaye ipholile ngexesha lokubumba, kukho uxinzelelo lwe-shrinkage ngaphakathi, olunokubangela ukuba iindawo zidibanise, njl. gcina ibhalansi yoxinzelelo lwenxalenye eyenziweyo.Emva kokugqitywa, inkxaso kwimodeli iya kususwa, kwaye umphezulu uphantsi kwaye uphuculwe nge-sander.Emva koko imodeli igqityiwe.

Nantsi indlela esebenza ngayo.

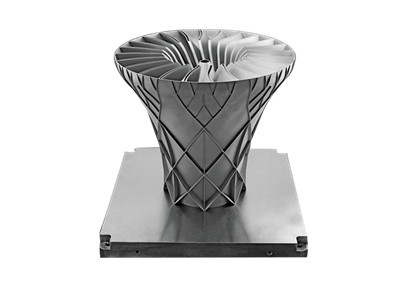

Ngaphantsi kolawulo lwekhompyutheni, i-laser iya kuhlanjululwa kwindawo ekhethiweyo, i-powder yensimbi iya kuncibilika, kwaye isinyithi esityhidiweyo siya kupholisa ngokukhawuleza kwaye siqine.xa ugqiba umgca omnye, i-substrate yokwenza i-substrate iya kuthoba ngobunzima bengqimba, kwaye emva koko i-powder entsha isetyenziswe yi-scraper.Le nkqubo ingentla iya kuphinda iphindwe de kube i-workpiece yenziwe.

Iingenelo

- Uxinaniso lwesinyithi olusemgangathweni olucutshungulwa yinkqubo ye-SLM ludlula i-99%, kwaye iipropathi ezigqwesileyo zomatshini zithelekiswa neenkqubo zemveli.

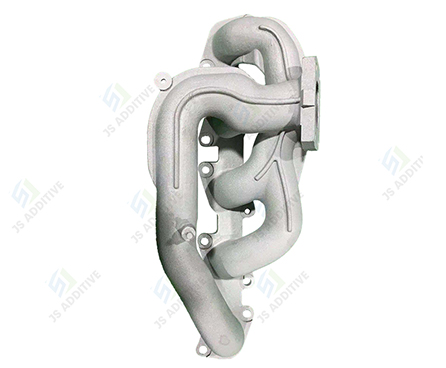

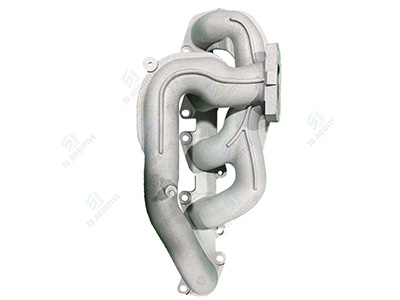

- Ukuyila ngokuthe ngqo kunye nokwenza iindawo ezisebenzayo zetsimbi ezinemilo yejometri enzima ngaphandle kweenkqubo eziphakathi

- Iindidi zezinto ezisetyenziswayo ziyaqhubeka zikhula, kwaye iindawo ezicutshungulwayo zinokudityaniswa kamva

- Lungiselela uyilo lwemveliso, buyisela umzimba oqinileyo wokuqala kunye nolwakhiwo oluntsonkothileyo nolunengqiqo ukuze ubunzima bemveliso egqityiweyo bube sezantsi, ngaloo ndlela kuncitshiswe iindleko zizonke.

Iingxaki

- Isantya esicothayo sokushicilela kunye nexesha elide lokuvelisa.

- Umphandle wemodeli erhabaxa, ifuna ukusetyenzwa ngasemva ukuze ubemhle ngakumbi.

- Umphezulu wemodeli erhabaxa kunye nokuchaneka okuphantsi.

Amashishini anoShicilelo lwe-SLM 3D

Amacandelo oLwakhiwo lweZakhiwo / aMacandelo eziThuthi / aMacandelo oKuhamba ngeenqwelomoya (Isiphekepheke) / ukuveliswa koomatshini / oomatshini boNyango / Ukwenziwa koMngundo / Amacandelo

iPost Processing

Inkqubo ye-SLM yahlulahlulwe ikakhulu kunyango lobushushu, ukuprinta kwentsimbi yokusika ucingo, ukupolisha, ukugaya, ukuqhushumba kwesanti njalo njalo.

Izinto ze-SLM

Ukunyibilika kweLaser eKhethekileyo (SLM) kunye neNsimbi eNgqongileyo yeLaser Sintering (DMLS) ziinkqubo ezimbini zokwenziwa kwesinyithi ezongezelelweyo ezizezosapho loshicilelo lwe-3D yebhedi yomgubo.Izinto ezisetyenzisiweyo kwinkqubo zizo zonke iintsimbi zegranular.

| I-SLM | Umzekelo | Uhlobo | Umbala | Ubuchwephesha | Umaleko ubukhulu | Iimbonakalo |

| Intsimbi engenaStinless | 316L | / | I-SLM | 0.03-0.04mm | Ukumelana nokugqwesa okugqwesileyo Ukusebenza kakuhle kwe-welding |

| Intsimbi yokungunda | 18Ni300 | / | I-SLM | 0.03-0.04mm | Iimpawu ezilungileyo zoomatshini Ukuxhathisa okugqwesileyo kwe-abrasion |

| Ingxubevange yeAluminiyam | I-AlSi10Mg | / | I-SLM | 0.03-0.04mm | Ukuxinana okuphantsi kodwa amandla aphezulu Ukumelana nokugqwesa okugqwesileyo |

| Ingxubevange yeTitanium | I-Ti6Al4V | / | I-SLM | 0.03-0.04mm | Ukumelana nokugqwesa okugqwesileyo Amandla athile aphezulu |