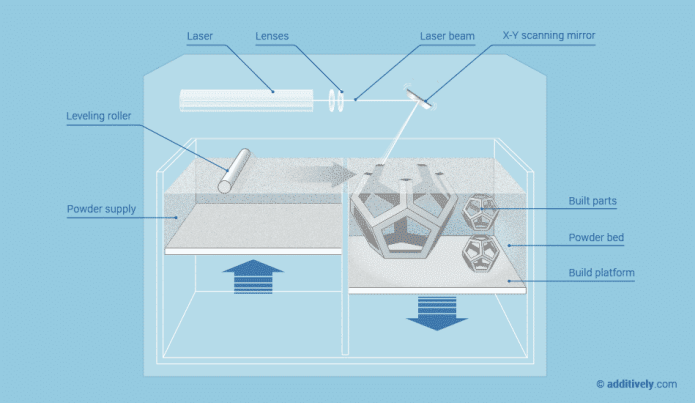

I-Selective Laser Sintering (SLS)ubuchwepheshe bokuphrinta be-3D obunamandla obuyingxenye yomndeni wenqubo ye-powder bed fusion engakhiqiza izingxenye ezinembayo neziqinile ezingasetshenziswa ngokuqondile ukuze zisetshenziswe ekugcineni, ukukhiqizwa kwenqwaba encane noma izingxenye ze-prototype.Phakathi nenqubo yokuphrinta yedivayisi ye-SLS, izinhlayiya ezincane zempushana yepulasitiki zincibilika zibe yisimo esifiswayo sezinhlangothi ezintathu kusetshenziswa i-laser enamandla amakhulu.I-laser ihlanganisa ngokukhetha impushanaizinto zokwakhangokuskena ingxenye yedatha enezinhlangothi ezintathu ebusweni bombhede oyimpuphu.Ngemva kokuskena isigaba ngasinye esiphambanayo, umbhede wempuphu wehliswa ungqimba olulodwa logqinsi, ungqimba olusha lwento yengezwa kuwo, futhi inqubo yokukhetha i-laser sintering iphindwa kuze kube yilapho ingxenye isiqediwe.

Ukuphrinta kwe-SLS 3Dingasetshenziswa kokubili ukwenza i-prototyping yezingxenye ezisebenzayo ze-polymer nezincaneukukhiqiza ugijimangenxa yezinga layo eliphezulu lenkululeko yokuklama, ukunemba okuphezulu, nokukhiqizwa kwezingxenye ezinezakhiwo ezinhle nezingaguquki zemishini.Njengoba isithombe esilandelayo sibonisa:

1.Inqubo Yokuphrinta

1.Inqubo Yokuphrinta

① Okokuqala, isisele nendawo yokwakha ziyashiswa ukuze kuvalwe izinga lokushisa elincibilikayoimpahla, bese kubekwa ungqimba lwempushana.

② Ilaser ibe isisetshenziswa ukuskena ingxenye enqamulayo yalolu ungqimba, ikhuphule izinga lokushisa lempushana lifike lapho lincibilika khona, bese ngokukhetha indawo ezophrintwa ukuze kwakhiwe ibhondi.

③ Ngemuva kokucwiliswa, iplatifomu yokwakha iyehla, i-scraper imbozwe ngolunye ungqimba lwezinto eziyimpushana, futhi okuqukethwe kwesinyathelo sesibili kuyaphindwa kuze kube yilapho kwakheka yonke imodeli.

④ Bese kuthi ngemva kokuphrinta, igumbi lokubumba liphole (imvamisa libe ngaphansi kwamadigri angu-40), futhi lingaqala ukususa izingxenye ukuze zicutshungulwe ngokulandelayo.

2. Izici

Inzuzo enkulu ye-SLSukuthi ayidingi isakhiwo sokusekela.I-powder engafakiwe inikeza konke ukusekelwa okudingekayo kwengxenye.Ngakho-ke, i-SLS ingasetshenziswa ukudala izimo zejometri zamahhala, inqobo nje uma ingaphakathi kwemingcele yenqubo yokunyathelisa, abaklami bangasebenzisa amathalenta abo njengoba befisa, ngaphandle kokukhathazeka ngokukhiqiza.

Uma uphrinta nge-SLS, ikakhulukazi ekukhiqizeni inqwaba encane, kubalulekile ukusebenzisa ngokugcwele ivolumu yonke yokwakha futhi ukhulise indawo yokuphrinta (isilinganiso sevolumu yomkhiqizo ophrintiwe kuwo wonke umgqomo wokuphrinta).Ngemva kokunquma ubude bokuphrinta obukhulu obusekelwe ezidingweni zesakhiwo semikhiqizo ephrintiwe, kuzothatha cishe inani elifanayo lesikhathi ukuphrinta, kungakhathaliseki inani lemikhiqizo ephrintiwe kusilawuli sokuphrinta.Lokhu kungenxa yokuthi isivinini sokusabalalisa sesendlalelo ngasinye sinquma isikhathi esiphelele sokuphrinta (ukuskena nge-laser kwenzeka ngokushesha okukhulu), futhi umshini kuzodingeka ujikeleze inombolo efanayo yezendlalelo.

Ngakho-ke, ngemboni ehlinzekaI-SLScubungula izinsizakalo zokuphrinta ze-3D, ingasebenzisa inani elikhulu lama-oda, futhi yandise inhlanganisela yemikhiqizo e-odwe ngangokunokwenzeka endaweni yokunyathelisa efanayo yokukhiqiza, okuzonciphisa kakhulu izindleko zokunyathelisa futhi kwandise isivinini sokunyathelisa.(Yehlisa isikhathi sokulinda ama-oda nokwenza ama-oda, bese uqala ukukhiqiza ngokushesha).

3. Ukucatshangelwa komklamo ongasindi

Njengoba i-SLS ayidingi izinto zokusekela, izingxenye ezinezingxenye ezingenalutho zinganyatheliswa kalula futhi ngokunembile.

Ingxenye engenalutho inciphisa isisindo kanye nezindleko zengxenye ngoba kusetshenziswa impahla encane, ebaluleke kakhulu emkhathini.Ngakho-ke, ngesikhathi sokuklanywa kwengxenye, noma ngesikhathi sokucutshungulwa kwedatha ngaphambi kokunyathelisa, kuyadingeka ukucabangela izimbobo zokuphunyuka ze-powder ukuze kukhishwe i-powder engafakiwe ngaphakathi kwengxenye (edlala indima esekelayo enqubweni ye-sintering. ).Kutuswa ukuthi wengeze okungenani izimbobo eziphunyukayo ezingu-2 ubukhulu obungu-5 mm kumklamo wakho.

Uma kudingeka ukuqina okukhulu, ingxenye kufanele iphrintwe iqine ngokuphelele.Enye inketho ukwenza umklamo ongenalutho, ukhiphe imbobo yokuphunyuka.Ngale ndlela, i-powder ehlanganiswe ngokuqinile izobanjwa engxenyeni, ikhulise ubukhulu bayo futhi inikeze ukusekelwa okwengeziwe ngokumelene nemithwalo yemishini ngaphandle kokuthinta isikhathi sokwakha.Isakhiwo segridi yekhekheba lezinyosi sangaphakathi singangezwa endaweni engaphakathi engenalutho ukuze kuthuthukiswe ukuqina kwengxenye.

4.Izinzuzo Nemikhawulo

a) Izinzuzo ezibalulekile

b) Izingxenye ze-SLS zinezakhiwo ezinhle zemishini ye-isotropic, ezizenza zilungele izingxenye ezisebenzayo nama-prototypes.

c) I-SLS ayidingi noma yikuphi ukwesekwa futhi ingakhiqiza kalula imiklamo enejometri eyinkimbinkimbi.

d) Amakhono okukhiqiza weI-SLSzilungele ukukhiqizwa kweqoqo elincane neliphakathi.

② Okubi kakhulu:

a) Ubulukhuni bengaphezulu kanye ne-porosity yangaphakathi yezingxenye ze-SLS kungase kudinge ukucubungula ngemva kokucubungula uma kufunwa indawo ebushelelezi noma ukucinana kwamanzi.

b) Ubulukhuni bengaphezulu kanye ne-porosity yangaphakathi yezingxenye ze-SLS kungase kudinge ukucutshungulwa uma kufunwa indawo ebushelelezi noma ukucinana kwamanzi.

4.Igama lokugcina

Insizakalo yobuchwepheshe yokuphrinta ye-SLS/MJF ye-JS Additive isekelwe ezintweni ze-HP enayiloni ezivame ukusetshenziswa emakethe -I-White/Grey/Black PA12 ne-MJF PA12 kanye ne-PA12GB, futhi ibonwa amakhasimende emazweni ahlukahlukene aphesheya kwezilwandle ngekhwalithi ephezulu.

Umnikeli:Nina