Isevisi Yokuphrinta ye-3D yobungcweti

Ukwethulwa kwe-SLM 3D Printing

I-SLM ubuchwepheshe obuthokozisayo obunezinhlelo zokusebenza eziningi ezingase zibe khona.Njengoba izimo zokusebenzisa zikhula, ubuchwepheshe buvuthwa, futhi izinqubo nezinto zokwakha ishibhile, kufanele sikubone sekuyinsakavukela, isetshenziswa kabanzi emikhakheni eminingi.

1- Yenza ungqimba olulandelayo lwe-powder layer, vimbela ukuskena nge-laser kongqimba lwempushana yensimbi ewugqinsi kakhulu futhi kudilike;

I-2- Ngemuva kokuthi i-powder ishisiwe, iyancibilika futhi ipholile ngesikhathi senqubo yokubumba, kukhona ukucindezeleka kokunciphisa ngaphakathi, okungabangela izingxenye ukuba zigoqe, njll. gcina ibhalansi yokucindezeleka yengxenye eyenziwe.Ngemuva kokuqedwa, ukusekelwa kumodeli kuzosuswa, futhi indawo engaphezulu igaywe futhi ipholishwe nge-sander.Khona-ke imodeli iyaqedwa.

Nansi indlela esebenza ngayo.

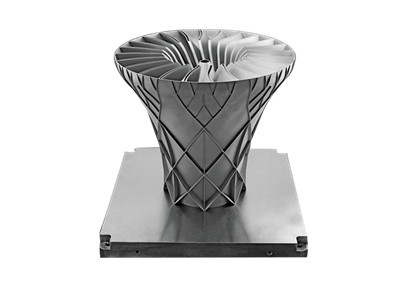

Ngaphansi kokulawulwa kwekhompiyutha, i-laser izothululelwa endaweni ekhethiwe, i-powder yensimbi izoncibilika, futhi insimbi encibilikisiwe izopholisa ngokushesha futhi iqine.lapho uqeda ungqimba olulodwa, i-substrate eyenza i-substrate izokwehliswa ngobuningi bengqimba, bese ungqimba olusha lwe-powder lusetshenziswa yi-scraper.Inqubo engenhla izophindwa kuze kube yilapho i-workpiece yakhiwe.

Izinzuzo

- Ukuminyana kwezinsimbi ezijwayelekile ezicutshungulwa yinqubo ye-SLM kudlula ama-99%, futhi izakhiwo ezinhle kakhulu zemishini ziqhathaniswa nezinqubo zendabuko.

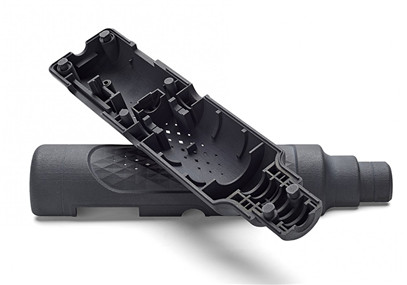

- Yakha ngokuqondile futhi wenze izingxenye ezisebenzayo zensimbi ezinobunjwa bejometri obuyinkimbinkimbi ngaphandle kwezinqubo eziphakathi nendawo

- Izinhlobo zezinto ezisetshenziswayo ziyaqhubeka nokwanda, futhi izingxenye ezicutshungulwayo zingashiselwa kamuva

- Lungiselela ukwakheka komkhiqizo, esikhundleni somzimba oqinile wasekuqaleni ngesakhiwo esiyinkimbinkimbi nesinengqondo ukuze isisindo somkhiqizo oqediwe sibe phansi, ngaleyo ndlela kwehlise izindleko zizonke.

Ukubi

- Isivinini sokuphrinta esinensayo nesikhathi eside sokukhiqiza.

- Indawo eyimodeli eqinile, idinga ukucutshungulwa ukuze yenziwe ibe yinhle kakhulu.

- Indawo yemodeli eqinile nokunemba okuphansi uma kuqhathaniswa.

Izimboni ezine-SLM 3D Printing

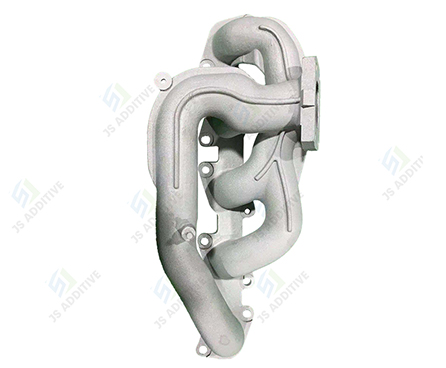

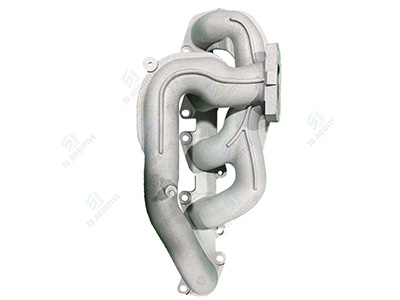

Izingxenye Zokwakha / Izingxenye Zezimoto / Izingxenye Zezindiza (I-Aerospace) / Ukukhiqizwa kwemishini / Imishini Yezokwelapha / Ukukhiqiza Isikhunta / Izingxenye

Ukuthunyelwa Kucutshungulwa

Inqubo ye-SLM ihlukaniswe ngokuyinhloko ekwelapheni ukushisa, ukunyathelisa kwensimbi ngocingo, ukupholisha, ukugaya, ukuqhunyiswa kwesihlabathi nokunye.

Izinto ze-SLM

I-Selective Laser Melting (SLM) kanye ne-Direct Metal Laser Sintering (DMLS) yizinqubo ezimbili zokukhiqiza izithasiselo zensimbi zomndeni wokuphrinta we-3D we-powder bed fusion.Izinto ezisetshenziswa kule nqubo zonke ziyizinsimbi ze-granular.

| I-SLM | Imodeli | Uhlobo | Umbala | Ubuchwepheshe | Ugqinsi lwesendlalelo | Izici |

| Insimbi Engenasici | 316L | / | I-SLM | 0.03-0.04mm | Ukumelana nokugqwala okuhle kakhulu Ukusebenza kahle kwe-welding |

| Insimbi yesikhunta | 18Ni300 | / | I-SLM | 0.03-0.04mm | Izakhiwo ezinhle zemishini Ukumelana okuhle kakhulu kwe-abrasion |

| I-aluminium Alloy | I-AlSi10Mg | / | I-SLM | 0.03-0.04mm | Ukuminyana okuphansi kodwa amandla aphezulu uma kuqhathaniswa Ukumelana nokugqwala okuhle kakhulu |

| I-Titanium Alloy | I-Ti6Al4V | / | I-SLM | 0.03-0.04mm | Ukumelana nokugqwala okuhle kakhulu Amandla athile aphezulu |