The Introduction of CNC Machining (Metal)

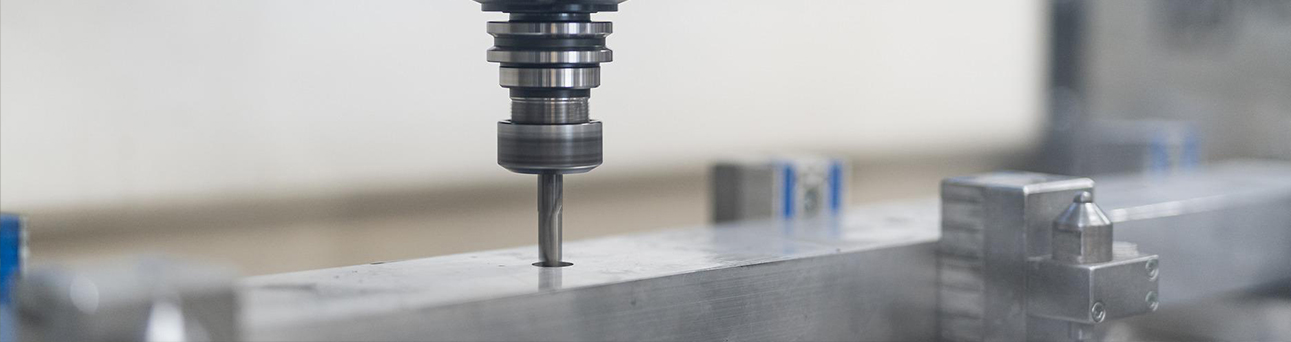

CNC Machining Metal is the use of numerical control machine tools to process metal and so on, also refers to the use of numerical control machining tools. CNC exponential machine tools are programmed and controlled by numerical control language, usually G code. The G code language of CNC machining tells the Cartesian position coordinates used by the machining tool of NC machine tools, and controls the feed speed of the tool and the spindle speed, as well as the functions of tool converter and coolant. Numerical control machining has great advantages over manual machining.

Here's how it works.

When CNC Metal is just started, three-axis origin restoration should be carried out to check whether the guide rail oil and spindle hydraulic oil of the machine are sufficient.

Not enough to timely refueling. The size of the processing workpiece should correspond to the drawings, even if only a small gap also have to ask the above management or programming.

In the process of processing the program is broken so when the program is also prone to error, must be checked in time. The XYZ axis should be zeroed out at the same time as the tool should be changed in processing.

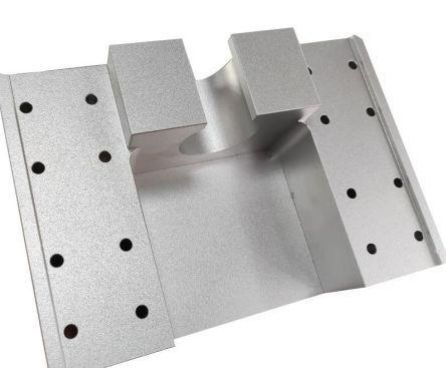

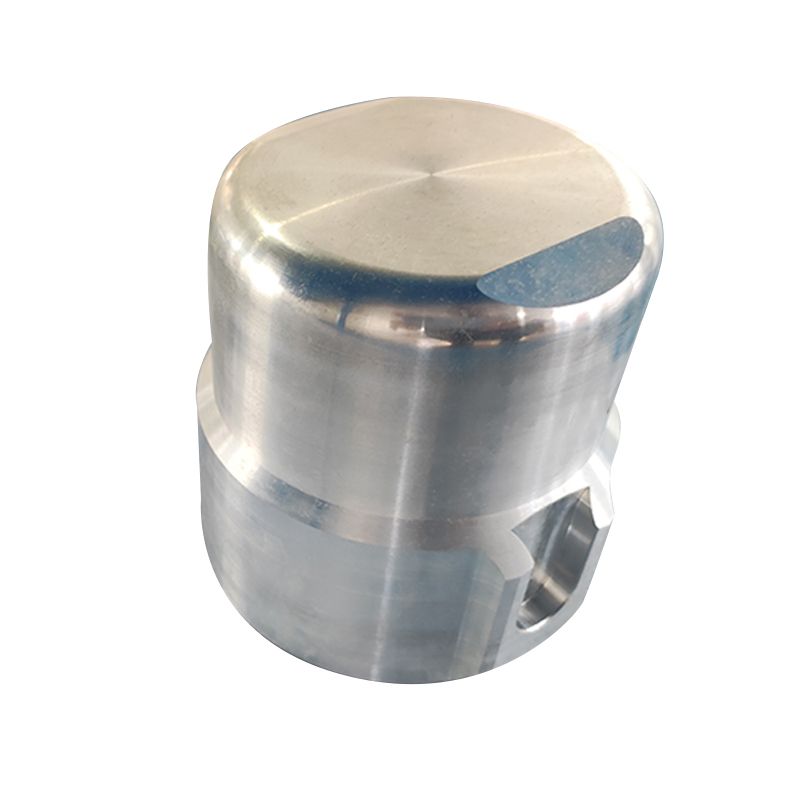

An example of general processing mainly include precision of pin hole, guide pin hole, insert groove, slotting, etc.

Easily in processing cutting knife: this is the experience of operating machine, beginners may not considering these aspects, since experience we should bear in mind that encountered in the processing of similar place their attention.

Advantages

- 1.The process is easy to program and can produce parts with simple geometry, with high accuracy.

- 2.It has high production capacities.

- 3.The cost of machining per part is relatively low.

- 4.3-axis CNC mills are less expensive than their 5-axis counterparts.

Disadvantages

- High technical requirements for operators and machine maintenance personnel.

- The purchase cost of machine equipment is expensive.

Industries With CNC Machining Metal

● ABS: White, light yellow, black, red. ● PA: White, light yellow, black, blue, green. ● PC: Transparent, black. ● PP: White, black. ● POM: White, black, green, grey, yellow, red, blue, orange.

Post Processing

For most metal materials, here are post processing techniques that are available from JSADD 3D.

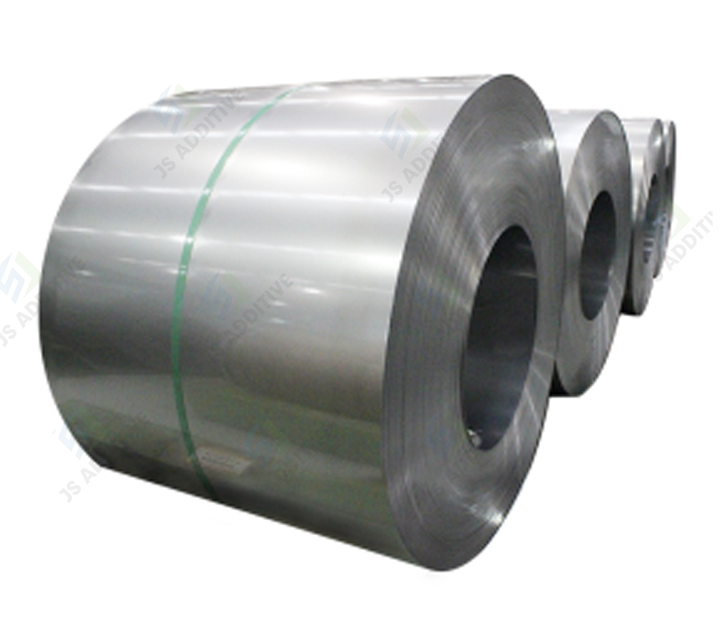

CNC Machining Metal Materials

JSADD 3D Provide CNC Machining Metal Materials: Aluminum Alloy,Brass,S45C,Q235 Steel, Sainless Steel, Titanium Alloy, D2 Steel, Magnesium Alloy

Best CNC Machining Metal Technique Service from JSADD 3D.