Ƙwararriyar Sabis na Buga 3D

Gabatarwar SLM 3D Printing

SLM fasaha ce mai ban sha'awa tare da aikace-aikace masu yawa. Yayin da shari'o'in amfani ke girma, fasaha na girma, kuma matakai da kayan aiki sun zama masu rahusa, ya kamata mu ga ya zama ruwan dare gama gari, ana amfani da shi sosai a fannoni da yawa.

1- Ɗauki na gaba Layer na foda mara kyau, hana Laser scanning na karfe mai kauri da kuma rushewa;

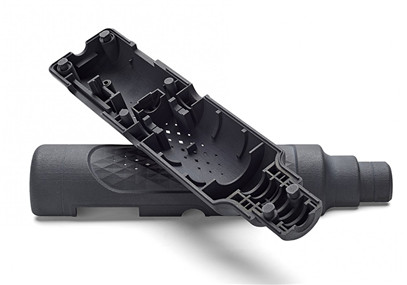

2- Bayan an dumama foda, narke da sanyaya yayin aikin gyaran jiki, akwai damuwa na raguwa a ciki, wanda zai iya haifar da sassa na jiki da sauransu. Bayan kammalawa, za a cire goyon baya a kan samfurin, kuma saman yana ƙasa kuma an goge shi da sander. Sa'an nan kuma samfurin ya kammala.

Ga yadda yake aiki.

Karkashin kulawar kwamfutar, za a kunna Laser din zuwa wurin da aka kebe, za a narkar da foda na karfe, kuma narkakkar za ta yi sanyi da sauri. Lokacin da aka gama Layer ɗaya, abin da aka samar zai ragu da kauri mai kauri, sa'an nan kuma a yi amfani da sabon foda ta hanyar scraper. Za a maimaita tsarin da ke sama har sai an kafa aikin aikin.

Amfani

- Matsakaicin daidaitattun karafa da tsarin SLM ke sarrafa ya wuce 99%, kuma kyawawan kaddarorin injin suna kwatankwacin matakan gargajiya.

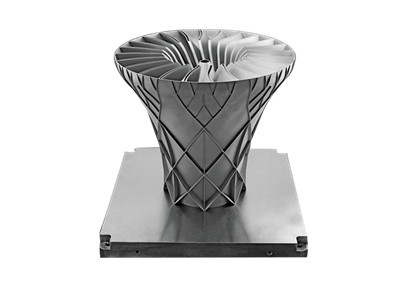

- Kai tsaye ƙira da ƙera sassan aikin ƙarfe tare da hadaddun siffofi na geometric ba tare da matakan tsaka-tsaki ba

- Nau'in kayan da ake amfani da su na ci gaba da karuwa, kuma sassan da aka sarrafa za a iya walda su daga baya

- Haɓaka ƙirar samfura, maye gurbin ƙaƙƙarfan asali na asali tare da tsari mai rikitarwa da ma'ana don nauyin samfurin da aka gama ya ragu, don haka rage ƙimar gabaɗaya.

Rashin amfani

- Saurari saurin bugawa da tsawon lokacin masana'antu.

- M samfurin saman, yana buƙatar bayan-aiki don sanya shi mafi kyau.

- M model surface da in mun gwada da low daidaito.

Masana'antu tare da SLM 3D Printing

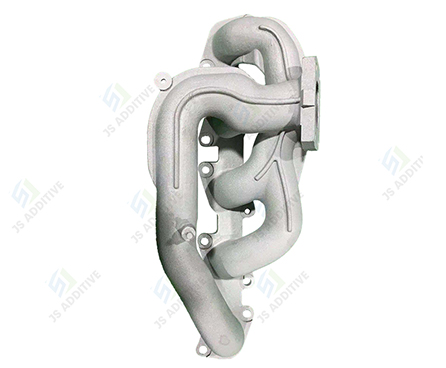

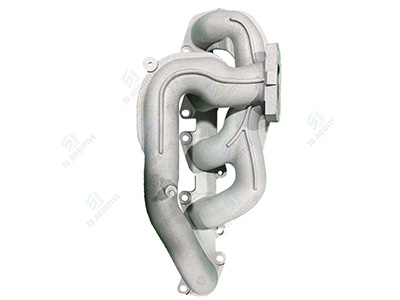

Sassan Gine-gine / Sassan Motoci / Sassan Jirgin Sama (Aerospace) / Masana'antar Injin / Injin Likitan Masana'anta / Sassa

Bayan Gudanarwa

Tsarin SLM ya kasu kashi biyu na maganin zafi, bugu na yankan karfe, goge goge, nika, fashewar yashi da sauransu.

SLM Materials

Zaɓin Laser Melting (SLM) da Direct Metal Laser Sintering (DMLS) matakai ne na masana'anta na ƙarfe guda biyu waɗanda ke cikin dangin bugu na 3D. Kayayyakin da ake amfani da su a cikin tsarin duk karafa ne na granular.

| SLM | Samfura | Nau'in | Launi | Fasaha | Layer kauri | Siffofin |

| Bakin Karfe | 316l | / | SLM | 0.03-0.04mm | Kyakkyawan juriya na lalata Kyakkyawan aikin walda |

| Mold Karfe | 18 Ni300 | / | SLM | 0.03-0.04mm | Good inji Properties Kyakkyawan juriya abrasion |

| Aluminum Alloy | AlSi10Mg | / | SLM | 0.03-0.04mm | Low yawa amma in mun gwada da babban ƙarfi Kyakkyawan juriya na lalata |

| Titanium Alloy | Ti6Al4V | / | SLM | 0.03-0.04mm | Kyakkyawan juriya na lalata Ƙarfi na musamman |

-

Whatsapp

-

Waya

-

Imel

-

WeChat

WeChat

-

Sama