Advantage

- High strength and strong toughness

- Accurate and dimensionally stable

- Excellent temperature resistance

- Good moisture resistance

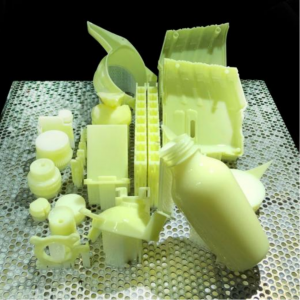

Ideal Applications

- Functional model need to be tough

- Conceptual model

- Low volume production models

- Automotive, aerospace, architecture, electronic applications

Technical Data-sheet

| Liquid Properties | Optical Properties | ||

| Appearance | Light yellow | Dp | 0.135-0.155 mm |

| Viscosity | 355-455 cps @ 28 ℃ | Ec | 9-12 mJ/cm2 |

| Density | 1.11-1.14g/cm3 @ 25 ℃ | Building layer thickness | 0.05~0.15mm |

| Mechanical Properties | UV Postcure | |

| MEASUREMENT | TEST METHOD | VALUE |

| Hardness , Shore D | ASTM D 2240 | 76-82 |

| Flexural modulus , Mpa | ASTM D 790 | 2,650-2,760 |

| Flexural strength , Mpa | ASTM D 790 | 65- 74 |

| Tensile modulus , MPa | ASTM D 638 | 2,160-2,360 |

| Tensile strength , MPa | ASTM D 638 | 25-30 |

| Elongation at break | ASTM D 638 | 12 -20% |

| Impact strength, notched lzod, J/m | ASTM D 256 | 58 - 70 |

| Heat deflection temperature, ℃ | ASTM D 648 @66PSI | 58-68 |

| Glass transition, Tg | DMA,E’peak | 55-70 |

| Density , g/cm3 | 1.14-1.16 | |

Recommended temperature for processing and storage of the above resin should be 18℃-25℃.

-

Low Density but Relatively High Strength SLM Al...

-

Excellent Transparency SLA Resin PMMA like KS15...

-

Popular 3D Print SLA Resin ABS like Brown KS908C

-

Durable Accurate SLA Resin ABS like Somos® GP P...

-

SLA Resin liquid photopolymer PP like White Som...

-

SLA Resin Durable Stereolithography ABS like So...