Professional 3D Printing Service

The Introduction Of Vacuum Casting

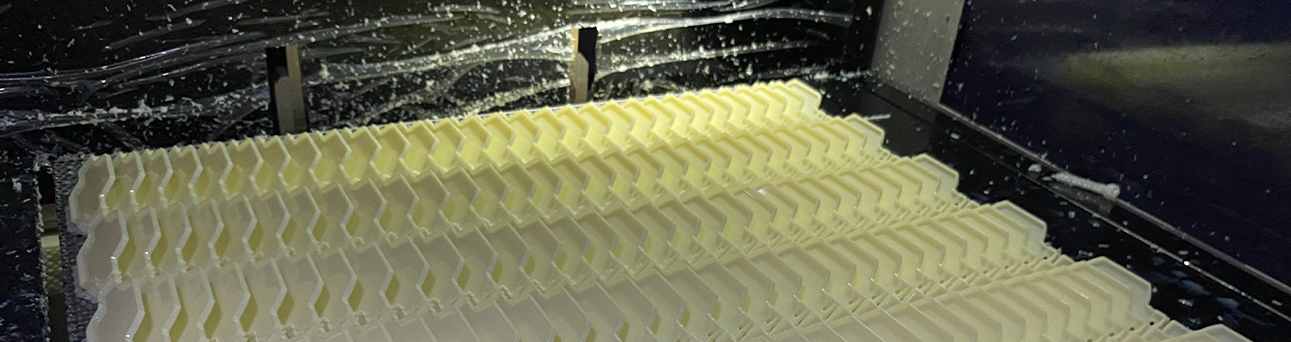

Computer numerical control (CNC) machining is a manufacturing process in which pre-programmed computer software controls the operation of tools and machinery in a factory. The process can be used to control a range of complex machines, from grinders and lathes to milling machines and CNC routers. With the help of CNC machining, three-dimensional cutting tasks can be completed with only a set of prompts.

In CNC manufacturing, machines are operated by numerical control, in which software programs are assigned to control objects. The language behind CNC machining, also known as G code, is used to control various behaviors of the corresponding machine, such as speed, feed rate and coordination.

Here's how it works.

In CNC manufacturing, machines are operated by numerical control, in which software programs are assigned to control objects. The language behind CNC machining, also known as G code, is used to control various behaviors of the corresponding machine, such as speed, feed rate and coordination.

Advantages

- 1.The process is easy to program and can produce parts with simple geometry, with high accuracy.

- 2.It has high production capacities.

- 3.The cost of machining per part is relatively low.

Disadvantages

- High technical requirements for operators and machine maintenance personnel.

- The purchase cost of machine equipment is expensive.

Industries with Vacuum Casting

● ABS: White, light yellow, black, red. ● PA: White, light yellow, black, blue, green. ● PC: Transparent, black. ● PP: White, black. ● POM: White, black, green, grey, yellow, red, blue, orange.

Post Processing

Since the models are printed using MJF technology, they can be easily sanded, painted, electroplated or screen printed.

MJF Materials

By SLA 3D printing, we can finish the production of large parts with very good accuracy and smooth surface. There are four kinds of resin materials with specific characteristics.

-

Whatsapp

-

Phone

-

E-mail

-

WeChat

WeChat

-

Top