Kaluwihan

- Kekuwatan dhuwur lan kateguhan sing kuwat

- Akurat lan dimensi stabil

- Resistance suhu banget

- Tahan kelembapan sing apik

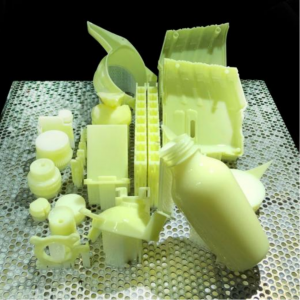

Aplikasi Ideal

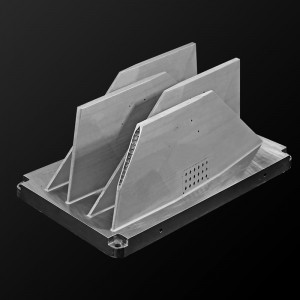

- Model fungsional kudu angel

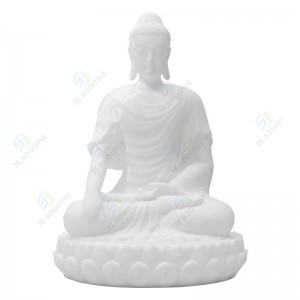

- Model konseptual

- Model produksi volume rendah

- Otomotif, aerospace, arsitektur, aplikasi elektronik

Lembar Data Teknis

| Sifat Cairan | Sifat Optik | ||

| Penampilan | Kuning cahya | Dp | 0,135-0,155 mm |

| Viskositas | 355-455 cps @ 28 ℃ | Ec | 9-12 mJ/cm2 |

| Kapadhetan | 1,11-1,14g/cm3 @ 25 ℃ | Ketebalan lapisan bangunan | 0,05 ~ 0,15 mm |

| Sifat Mekanik | UV Postcure | |

| PENGUKURAN | METODE UJI | NILAI |

| Hardness, Shore D | ASTM D 2240 | 76-82 |

| Modulus lentur, Mpa | ASTM D 790 | 2.650-2.760 |

| Kekuatan lentur, Mpa | ASTM D 790 | 65-74 |

| Modulus tarik, MPa | ASTM D 638 | 2.160-2.360 |

| Kekuatan tarik, MPa | ASTM D 638 | 25-30 |

| Elongation ing break | ASTM D 638 | 12 -20% |

| Kekuwatan impact, notched lzod, J/m | ASTM D 256 | 58 - 70 |

| Suhu defleksi panas, ℃ | ASTM D 648 @66PSI | 58-68 |

| Transisi kaca, Tg | DMA, E'peak | 55-70 |

| Kapadhetan, g/cm3 | 1.14-1.16 | |

Rekomendasi suhu kanggo Processing lan panyimpenan saka resin ndhuwur kudu 18 ℃ -25 ℃.