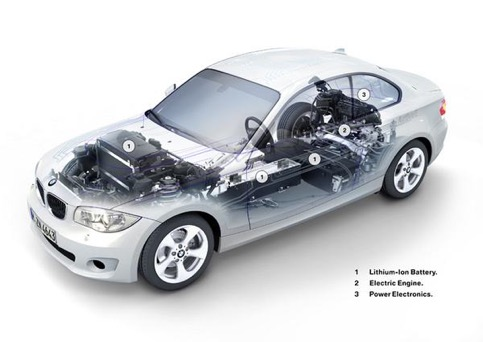

In recent years, new energy vehicles represented by electric vehicles have become a new trend in the development of the automobile industry. Flame-retardant materials widely used in new energy vehicles are increasingly attracting people’s attention, especially the plastic parts used in charging piles, battery parts and other links all require flame-retardant.

Application of flame-resistant material in charging gun

As an electric vehicle charging connector, the charging gun is an important connection component connecting charging facilities such as charging piles and electric vehicles. The quality of the charging gun directly influences the charging performance and safety. Charging gun shell material requirements are relatively high, commonly used materials are: PBT+GF (glass fiber reinforced thermoplastic polyester), PA+GF (glass fiber reinforced nylon), weather PC, etc.

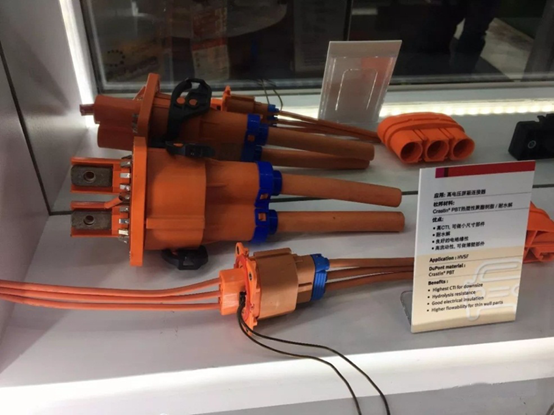

Application of flame-resistant material to automotive connectors

The basic requirements of connector materials are heat and flame retardant. Because the connector contact parts are metal and the number of plugging and pulling is high, the materials are required to have nice flame and heat resistance, avoid fire and ensure safety. At present, thermoplastic engineering plastics such as PBT, PPS, PA, PPE and PET are commonly used for connectors.

Application of flame-resistant materials in battery modules

The structural component of the battery box is the elementary component of the battery system. Its main function is to support and fix the battery module, so as to avoid the damage of the battery box and its internal parts under the action of mechanical stress or external force, which is of great significance for the mechanical safety of the battery pack. Battery case housing and supporting components have high requirements for comprehensive material properties such as flame retardant, heat resistance, tensile strength and impact strength. Nylon (PA) materials are mostly used, and PA6 is the majority at present.

Application of flame-resistant material in plug and socket

The main flame-resistant materials used on plugs and sockets are PVT-GF25 FR, PVT-GF30 FR (glass fiber reinforced thermoplastic polyester) or PA66-GF25 FR/PA66-GF30 FR and PA66-GF25 FR/PA66-GF30 FR (glass fiber reinforced Nylon), The application material is demanded to be halogen-free flame retardant, which does not produce carcinogenic smoke and corrosive gases during combustion.

JSADD 3D provides professional 3D printing service, we can use a wide variety of flame-retardant materials to print product models to meet your needs.

Contributor: Vivien