Are SLA 3D printed parts and prototypes watertight? The answer is yes, they definitely are.

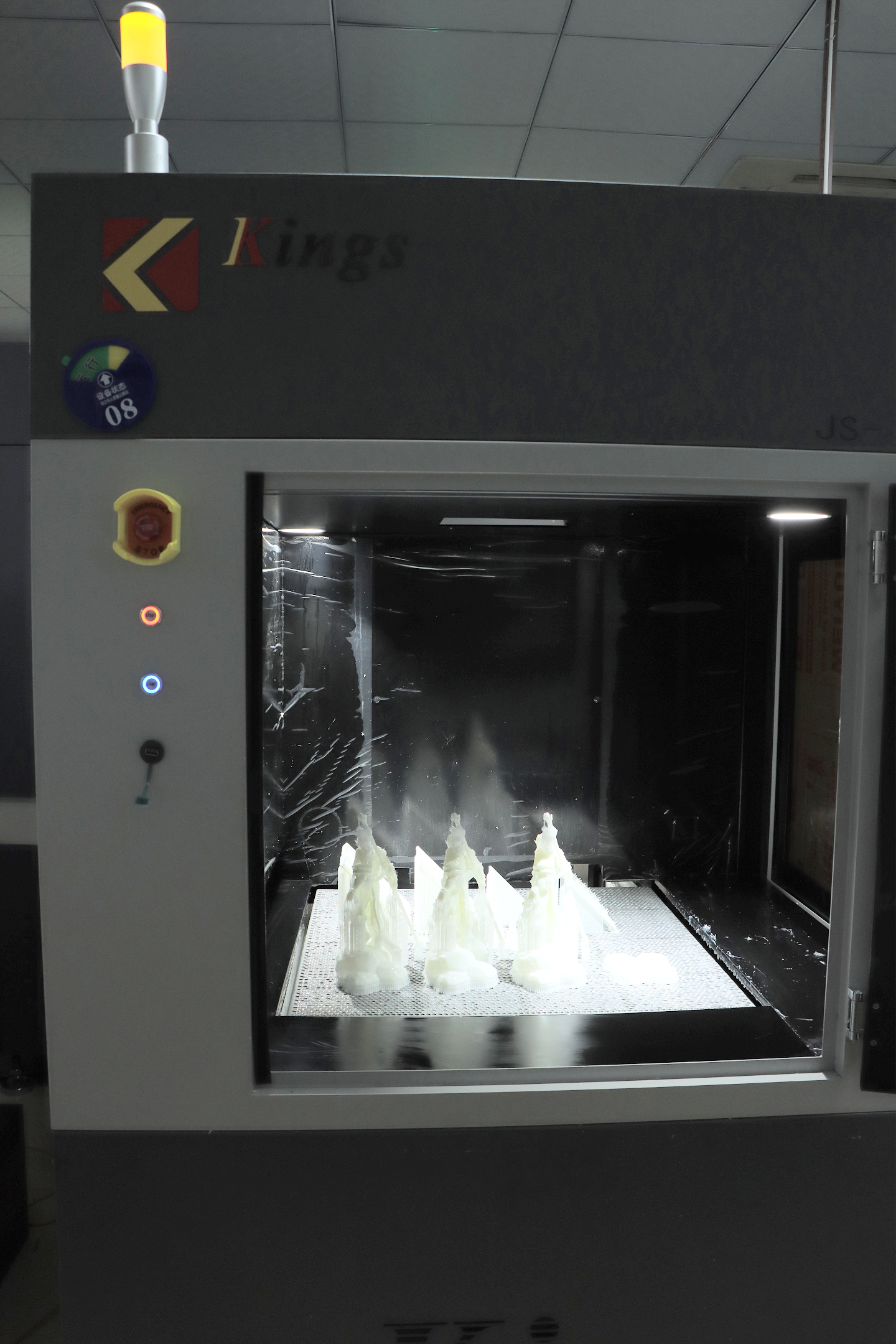

Stereolithography, often refered to as SLA, it works by focusing ultraviolet laser onto a vat of photo polymer resin. The resin is photo-chemically solidified and a single layer of desired 3D object is formed, the process of which is repeated for each layer until the model is completed.

The raw material for SLA is a photosensitive liquid resin. This photosensitive resin material is highly sensitive to the light, they will quickly produce a polymerisation reaction under the irradiation of the laser to complete the curing. During this process, the photosensitive resin material is completely waterproof and does not react with water in any way. This is the main reason that SLA 3D printed parts and prototypes have good waterproof characteristics.

As we all know, SLA products have a smooth surface and good details. Compared with FDM printed parts, SLA products have no printing lines; compared with nylon printed products, the surface of SLA products is non-porous and water cannot penetrate.

In addition to this, SLA-printed components have great tolerances, so that there is almost no air gap between the multiple components, and when assembled together with seals or gaskets, the enclosure is not only completely waterproof, but also able to withstand enormous pressure.

Moreover, SLA also has many advantages such as fast moulding, high temperature resistance and good toughness. However, it is worth noting that photosensitive resin materials will gradually become brittle and yellow under long-term outdoor light environment, so they are not suitable for outdoor using. If it is to be used in water and subjected to a certain amount of pressure, it will be a very suitable choice.