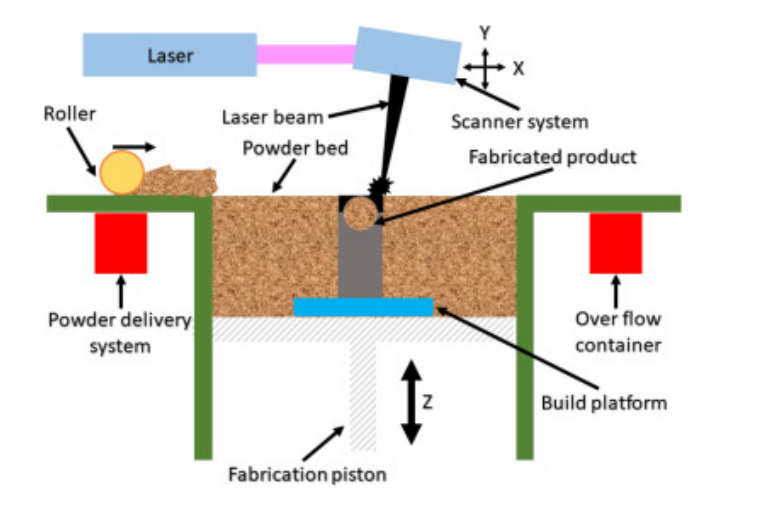

Selective laser melting (SLM)is a comparatively newer 3D-printing technology and developed in 1995 by German scientists. Similar to SLA where UV laser is used, a high-powered laser beam is used in SLM to form 3D parts. During the printing process, the laser beam melts and fuses various metallic powders together. As the laser beam hits a thin layer of the material, it selectively joins or welds the particles together.

After one complete print cycle, the printer adds a new layer of powered material to the previous one. The object is then lowered by the precise amount of the thickness of a single layer. When the print process is complete, someone will manually remove the unused powder from the object. The main difference between SLM and SLS is that SLM completely melts the powder, whereas in SLS, only partly melted or sintered powdered is used. In general, SLM end products tend to be stronger as they have fewer or no voids.

A common use for SLM printing is with 3D parts that have complex structures, geometries and thin walls. The aerospace industry uses SLM 3D printing in some of its pioneering projects. These are typically those which focus on precise, durable, lightweight parts. SLM is quite widespread now among the aerospace and medical orthopedics industries. Those who invest in SLM 3D printers include researchers, universities, metal powder developers and others, who are keen to explore the full range and future potential of metal additive manufacturing.

Advantages and limitations of selective laser melting

SLM technology enables the manufacturing of geometries that include complex features that are not possible with conventional manufacturing methods such as casting, powder metallurgy, forging, and extrusion. Like other AM techniques, manufacturing of biomedical devices by SLM has an economic impact as it allows short production runs without significant cost penalties.

In particular, compared to conventional manufacturing techniques, SLM is suited for the biomedical device manufacturing because of the following capabilities:

1.It allows manufacturing of prototype device components, for design validation purposes before mass production runs.

2.SLM technology enables low-volume production components, especially during the initial design deployments, which allows rapid implementation of any design changes.

3.This technology like other AM techniques result in shorter product life cycle through flexible production stages which ensure shorter time-to-market of the manufactured devices.

4.There are practically no constraints in fabrication of any complex shaped geometries via SLM technology. Biomedical device components that are not technically feasible to fabricate with other conventional methods, for example, complex porous scaffolds and components with designed porosities, can be precisely fabricated by SLM.

5.Fabrication of biomedical devices by SLM does not require any additional expensive tooling or extensive assembly requirements, thus directly reducing the production costs.

6.SLM technology permits complexity and customization of biomedical devices for free.

7.Optimization of various processing parameters of SLM results in part densities up to 99.98% for Ti alloys, allowing mechanical properties of the fabricated parts, their corrosion behavior, and process accuracies to fulfill requirements for medical or dental parts manufacturing.

JS ADD 3D Printing is China top professional SLM printing manufacturer.

Popular metal material:

Stainless steel

Aluminum

Titanium

Some Uncommon metal materials we can also print such as :Copper Chromium Zirconium Alloy / tin bronze alloy / Nickel-based super alloy/ cobalt chromium alloy etc.

Advantages:

Reduces production time and reduce time to market

No limit on shapes highly complex components

Ideal for small parts with significant complexity

Max printing size: 620*620*1100mm (stainless steel)168*168*150mm(kinds of material)

Hope we can have the chance to provide you SLM printing services. Your satisfaction is our priority, following are some SLM printing samples we did for your reference.