3D bioprinting is a highly advanced manufacturing platform that can be used to print tissues from cells and ultimately vital organs. This could open up new worlds in medicine while directly benefiting patients who need organ replacement.

Instead of waiting for a suitable donor or risking the body rejecting the transplanted organ, patients have a purpose-built custom organ to replace a defective one. However, even with the advances in 3D bioprinting over the past 20 years, it still lacks significant progress in order to produce complex 3D biomimetic tissue constructs.

According to researchers at Singapore University of Technology and Design (SUTD), Nanyang Technological University (NTU) and Asia University, tissue culture technologies in particular need to be accelerated to address the bottleneck in maturing bioprinted multicellular 3D tissue constructs into functional tissues. Their research paper, titled “Print me an organ! Why haven’t we shown up yet?” has been published in Advances in Polymer Science.

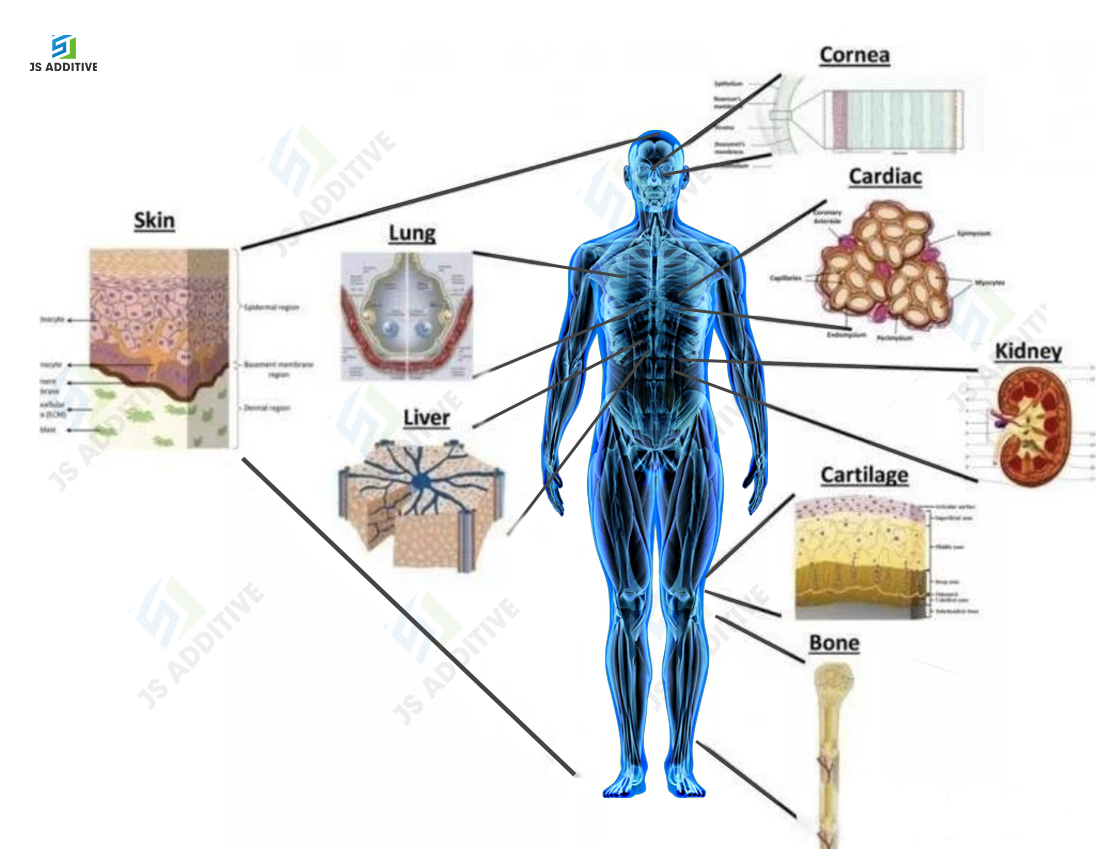

In this paper, the researchers also provide an in-depth review of recent improvements and analyze bioprinting technologies.The progress in bioink development, implementation of new bioprinting and tissue maturation strategies are also be analyzed. Particular attention is also given to the role of polymer science and how it complements 3D bioprinting to overcome some of the major hurdles in the field of organ printing, such as enabling biomimetic, angiogenesis and 3D anatomy-related biological structures (as the below images show).

The use of complementary strategies, such as dynamic co-culture perfusion systems, is considered essential to ensure the maturation and assembly of bioprinted tissue constructs. Even though it is now possible to manufacture human-scale tissues or organs that may mature into vascularized and partially functional tissues, the industry still lags behind in the bioprinting of human-specific tissues or organs due to the complexity of tissue-specific extracellular matrix (ECM) and tissue maturation process – lack of suitable co-culture media to support multiple cell types and requires further tissue conditioning prior to engraftment.

“While 3D bioprinting is still in its early stages, the remarkable leaps it has made in recent years suggest the ultimate reality of lab-grown functional organs. However, to push the frontiers of medicine, we must overcome the technical challenges of fabricating tissue. Specific bioinks do not Optimizing the tissue maturation process. This will ultimately have a huge impact on the lives of patients, many of whom may depend on the future of 3D bioprinting,” said Professor Chua Chee Kai, lead author of the paper.

JS Additive‘s 3D printing service has also been continuously developing and advancing,which reachs a more advanced level in the medical industry to meet the needs of major patients and scientific research. Our 3D printed medical models and finished products are also widely used in overseas applications. Welcome and use.