-

What is Vacuum Casting Service?

Introduction of Vacuum Casting Vacuum casting or silicon mould refers to the use of the original prototype, the production of silicone mould in a vacuum state, and the use... -

Introduction to the Coloring Process of JSADD 3D

The main process of 3d printing is: 3d modeling ,3d printing 3d printing post-processing As long as there are 3d printers in the 3d printing process, many people can do it, but the 3d printing post... -

What is SLA 3D Printing Technology Service?

SLA is short for ‘Stereo lithography Appearance’, which stands for three-dimensional light-curing forming. A laser of a specific wavelength and intensity is focused on the surface of th... -

How many steps are involved in customising a pair of 3D printed glasses?

People have five senses: “sight, hearing, smell, taste and touch” complement each other, and generally people have a more complete sense of things after integrating these five kinds of ... -

Introduction to SLA 3D printing

1.Why choose SLA 3D printing? There are many reasons to use SLA printing. If your project requires fine features, smooth surface finishes, part accuracy and precision, isotropy, mechanical properti... -

Characteristics and industry application of glass fiber reinforced nylon

SLS Nylon and glass fiber are both excellent materials in their own right, and their composite materials combine their strengths. The strength and rigidity are much higher than those of unreinforce... -

What are the differences between electroplating, vacuum plating, ion plating and spray plating?

Electroplating is the process of using the principle of electrolysis to plate a thin layer of other metals or alloys on some metal surfaces, which is the process of using electrolysis to attach a l... -

How to post-cure a light-cured 3D printed prototype once it has been completed

After the prototype has been formed in the liquid resin, the lifting table lifts it out of the liquid and removes it and starts the post-treatment such as finishing and sanding. A thin spatula is i... -

What are the post-processing steps of 3D printing?

For those who are new to 3D printing, they all have this problem. Other people’s printed works are shiny and vivid, and they look high class, while their printed models are hairy and unforgiv... -

A detailed comparison of the principles and characteristics of five different types of metal 3D printing technology (Part II)

Electron Beam Melting (EBM) Electron Beam Selective Melting (EBSM) Principle Similar to laser selective sintering and Selective Laser Melting processes, electron beam selective melting technology... -

A detailed comparison of the principles and characteristics of five different types of metal 3D printing technology (Part I)

With the development of science and technology and the promotion of the application of demand, the use of rapid prototyping to directly manufacture metal functional parts has become the main develo... -

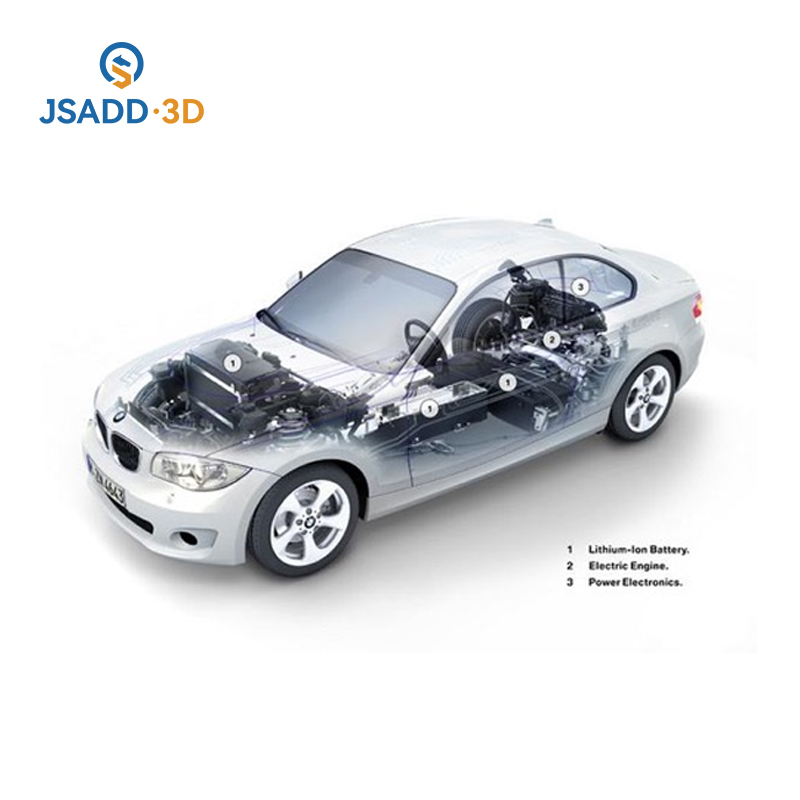

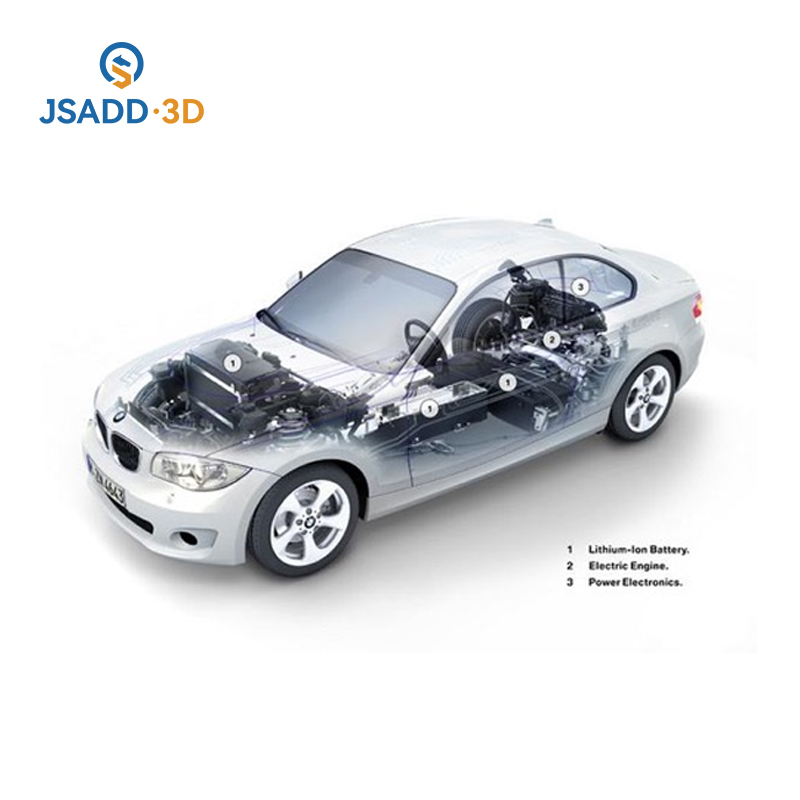

Application of flame-resistant material in the field of new energy vehicles

In recent years, new energy vehicles represented by electric vehicles have become a new trend in the development of the automobile industry. Flame-retardant materials widely used in new energy vehi...

-

Whatsapp

-

Phone

-

E-mail

-

WeChat

WeChat

-

Top