-

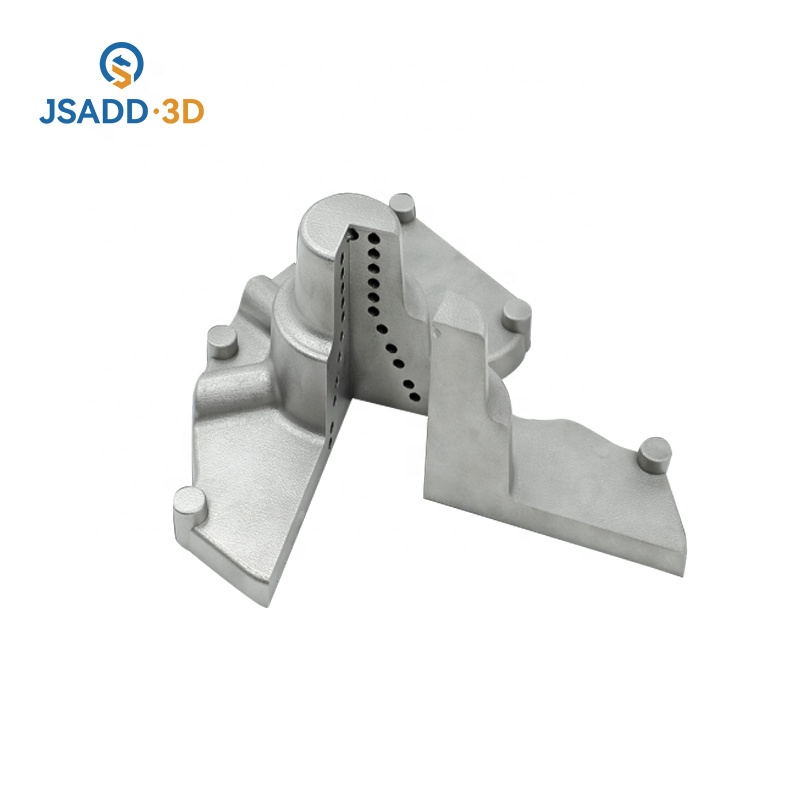

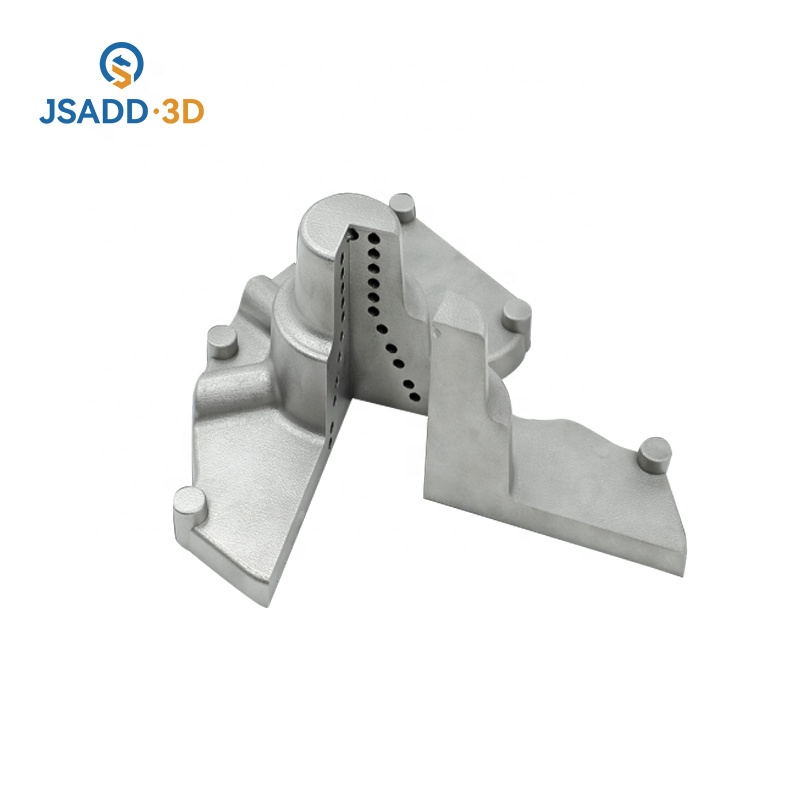

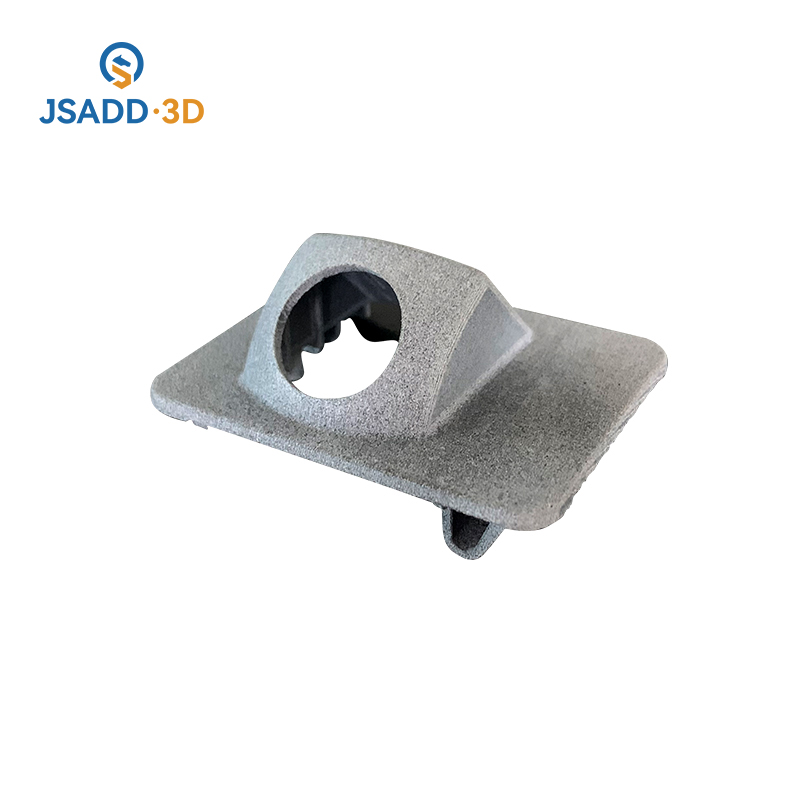

What’s the SLM Process in 3D printing?

Selective Laser melting (SLM) , also known as laser fusion welding, is a highly promising additive manufacturing technology for metals that uses high energy laser light to... -

Listen to SLM Solutions explain Free Float 3D printing technology

On June 23, 2021, SLM Solutions officially launched Free Float, a new unsupported technology for metal additive manufacturing that opens up a higher degree of freedom for ... -

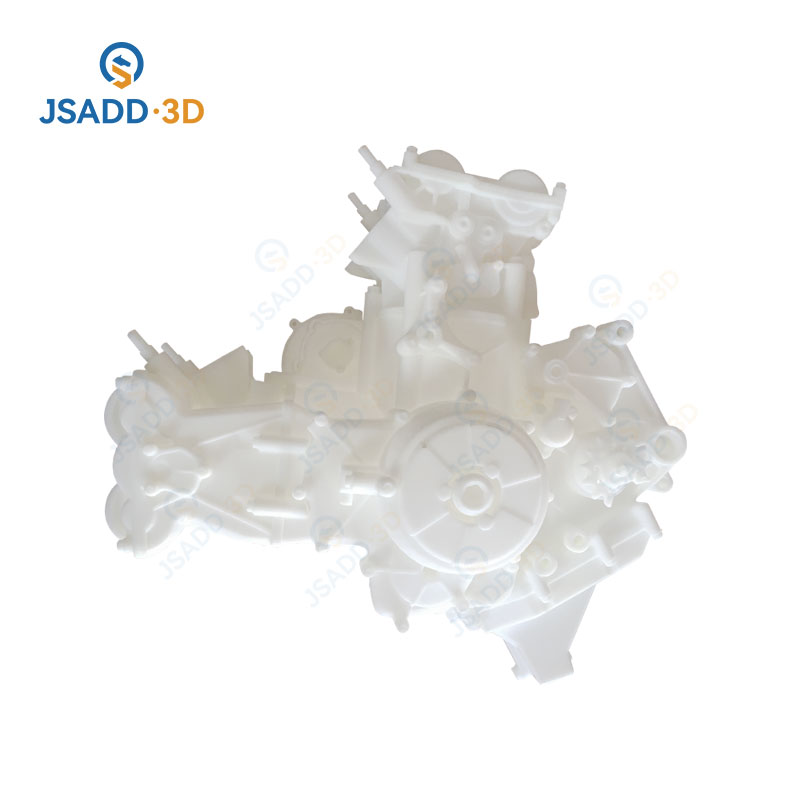

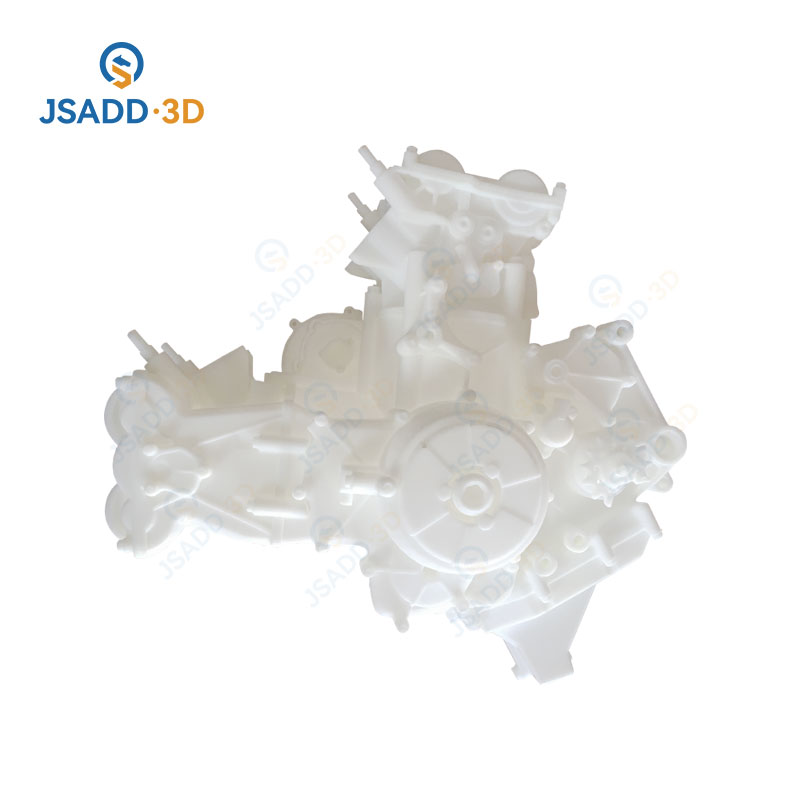

what are the advantages of SLS material?

Nylons are a common class of plastics that have been around since the 1930s. They are a polyamide polymer traditionally used in a number of common plastic manufacturing pr... -

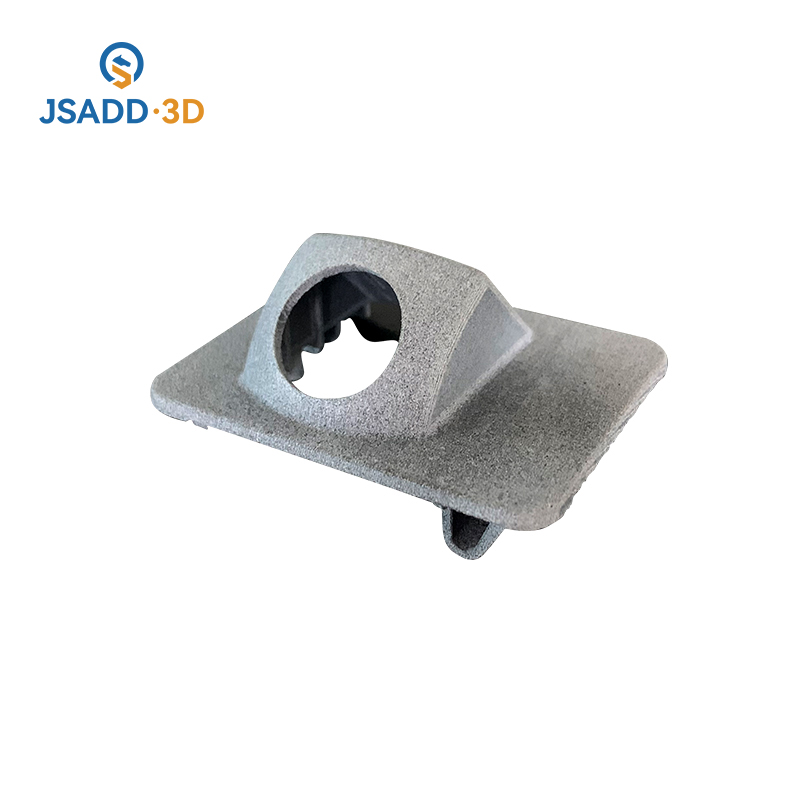

What is SLS 3D Printing Service?

Introduction of SLS 3D Printing SLS 3D printing is also known as powder sintering technology. SLS printing technology uses a layer of powder material laid flat on the uppe... -

New Discoveries In SLM Additive Manufacturing

On July 13, 2023, Prof. Gang Wang's team at the Institute of Materials Research of Shanghai University published their latest research results "Microstructural evolution a... -

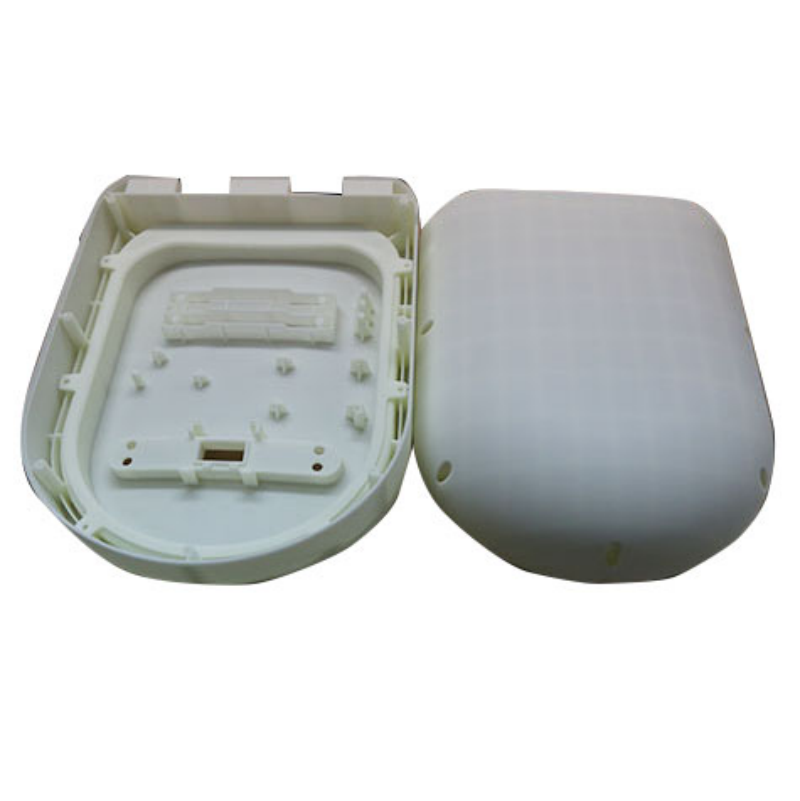

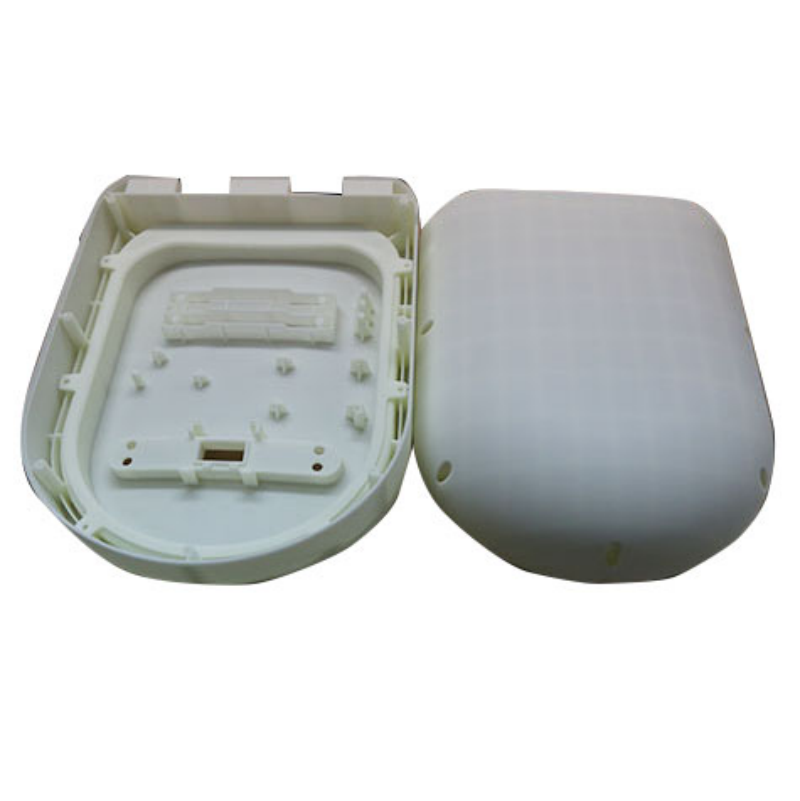

What is SLA 3D printing service?

Stereolithography (SLA or SL; also known as vat photopolymerisation, optical fabrication, photo-solidification, or resin printing is a form of 3D printing technology used ... -

How does SLA 3d printing work?

SLA technology, known as Stereo lithography Appearance, uses a laser to focus on the surface of a light-cured material, causing it to solidify sequentially from point to line and from line to surfa... -

Why use SLA 3D printing?

SLA 3D printing is the most common resin 3D printing process that has become vastly popular for its ability to produce high-accuracy, isotropic, and watertight prototypes ... -

What is 3D printing?

On August 31, Apple is said to be introducing 3D printing technology to produce steel chassis for smart watches. In addition, Apple plans to start 3D printing titanium dev... -

What is the difference between FDM and SLA ?

As the two most common 3D printing processes, FDM and SLA printing are widely used in different industrial fields. FDM is a 3D printing technology based on the principle o... -

What are the benefits of using an SLA 3D printer?

If you want to use 3D printing technology for product prototyping, appearance verification, size and structure verification, SLA light curing 3D printers are a good choice... -

What is the difference between SLA and SLS printing?

With the gradual maturity of 3D printing technology, 3D printing has been widely used. But people often ask, "What's the difference between SLA technology and SLS technolo...

-

Whatsapp

-

Phone

-

E-mail

-

WeChat

WeChat

-

Top