If you want to use 3D printing technology for product prototyping, appearance verification, size and structure verification, SLA light curing 3D printers are a good choice. Here are the advantages and benefits of SLA 3D printing technology compared with traditional processes:

1.Time

SLA 3D printing technology improves work efficiency, SLA light curing 3D printer integrated molding, reduce a lot of redundant steps, SLA 3D printing enables designers to quickly make prototypes of items conceived in their minds, and ultimately save time in the design process. This allows new or improved products to get to market faster than traditional methods.

2. Space

An industrial-grade 3D printer occupies a small area, and dozens of 3D printing machines can be placed in a small factory building, saving a lot of space.

3. The environment

The traditional process of making large sculpture crafts, generally using gypsum, glass steel to turn the mold, during which a lot of dust pollution and waste materials will be generated. The use of SLA 3D printer to produce products, no dust, no waste, no pollution, no fear of environmental risks.

4. The cost

SLA 3D printing technology reduces a lot of costs, SLA 3D printers are intelligent manufacturing, no human caretaker, reduce labor costs, because SLA 3D printing utilizes the concept of adding materials rather than subtracting materials, so the process is almost waste. While the materials used in traditional manufacturing methods are recyclable, the process of recycling the materials costs money, and the SLA 3D printer offers significant cost savings.

5. Complexity

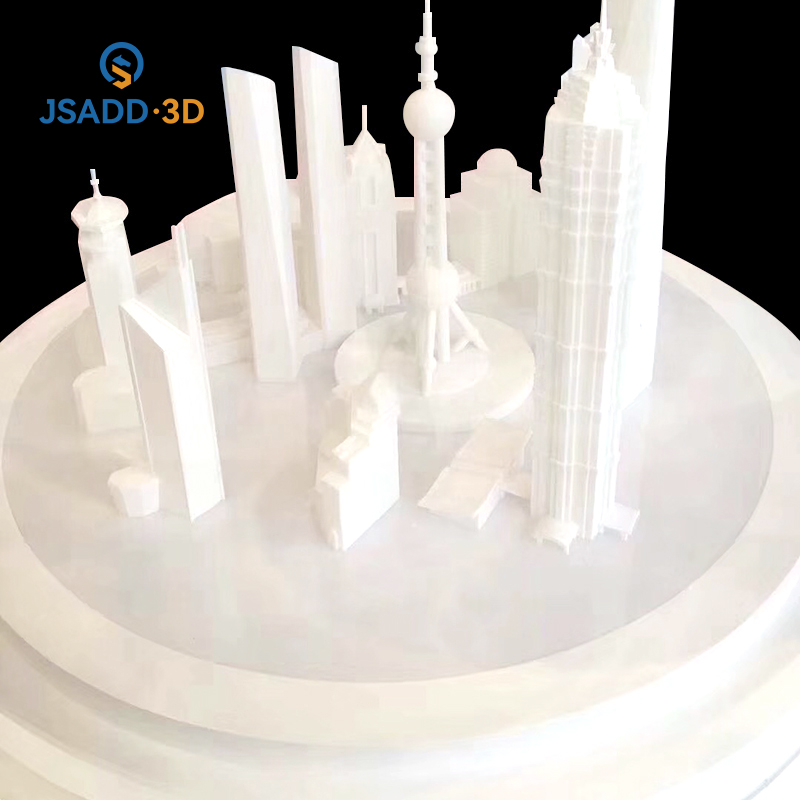

SLA 3D printing technology is not affected by complexity, accurate printing of complex parts, many traditional processes can not be made hollow, hollow structure can be completed through 3D printing and personalized customization of different product needs, complex hand plate model assembly verification, can directly print the model for product assembly verification is suitable, and then open mold mass production.

The advantage of JSADD 3D company 's 3D printer is that the maximum size is 17000*800*600mm, which can help customers achieve integrated printing of products, faster.

If you want to know more information, Welcome Contact US

Contributor: Alisa / Lili Lu / Seazon