SLA (Stereo Lithography Apparatus) is a 3D printing technology that uses ultraviolet laser to cure a liquid photopolymer resin layer by layer into the desired 3D object. There are many materials that can be used in SLA 3D printing processes. SLA materials used by JS ADD can be classified into the following four categories based on their properties: ABS-like resin, PMMA-like resin, rubber-like resin, and PP-like resin. To realize the function and application of the target product, the characteristics of different materials should be taken into account when selecting the materials.

ABS-like resin is a type of 3D printing resin designed to mimic the properties of ABS (Acrylonitrile Butadiene Styrene) plastic. It offers similar characteristics such as strength, durability, and impact resistance, making it suitable for applications requiring tough and durable parts. ABS-like resin is commonly used in stereolithography (SLA) 3D printers, providing users with a balance between print quality and mechanical performance similar to traditional ABS plastic. The following table lists the ABS-like resins used in JS ADD and their characteristics.

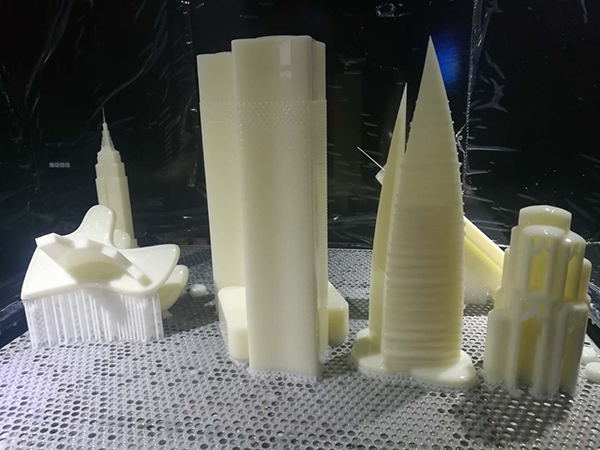

PMMA-like resin, is a synthetic polymer material that shares similarities with PMMA (polymethyl methacrylate). It possesses comparable properties such as transparency, weather resistance, and durability, making it suitable for various applications in industries like optics, automotive, and construction. PMMA-like resin is valued for its ability to be molded into intricate shapes while maintaining optical clarity, making it a versatile choice in manufacturing processes where both aesthetics and functionality are critical. The following table shows the PMMA-like resin used in JS ADD and its characteristics.

Rubber-like resin is a type of polymer material designed to mimic the properties of natural rubber. It offers flexibility, elasticity, and resilience, similar to rubber, but can be easily molded and processed like other synthetic resins. This makes rubber-like resin ideal for applications requiring soft-touch surfaces, shock absorption, or stretchability, such as in consumer products, footwear, and medical devices. The following table shows the Rubber-like resin used in JS ADD and its characteristics.

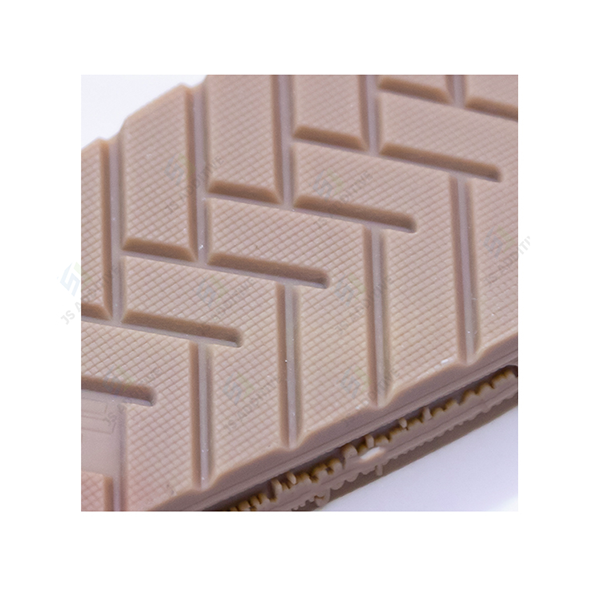

PP-like resin refers to a synthetic polymer material that exhibits similar properties to polypropylene (PP). It is known for its versatility, durability, and resistance to chemical and thermal degradation. PP-like resin can be easily molded into various shapes and forms, making it suitable for a wide range of applications in industries such as packaging, automotive, and consumer goods. This resin is valued for its lightweight nature, excellent moisture resistance, and ability to maintain structural integrity under different environmental conditions. Its affordability and recyclability further contribute to its popularity in manufacturing processes worldwide. The following table shows the PP-like resin used in JS ADD and its characteristics.