SLA is short for ‘Stereo lithography Appearance’, which stands for three-dimensional light-curing forming. A laser of a specific wavelength and intensity is focused on the surface of the light-cured material, causing it to solidify sequentially from point to line and from line to surface, completing one layer of the drawing process, and then moving the lift table in the vertical direction by the height of one layer to cure another. The layers are thus stacked to form a three-dimensional entity.

SLA is the earliest practical rapid prototyping technology, using liquid photosensitive resin raw material. The process is, first of all, to design a three-dimensional solid model through CAD, using discrete programs to slice the model, design the scanning path, the data generated will precisely control the movement of the laser scanner and lifting platform; The laser beam shines on the surface of the liquid photosensitive resin according to the designed scanning path through the scanner controlled by the numerical control device, so that a layer of resin in a specific area of the surface after curing, when a layer is finished, a section of the part is generated; Then the lifting platform drops a certain distance, the curing layer is covered with another layer of liquid resin, and then the second layer is scanned. The second curing layer is firmly bonded to the previous curing layer, so that the layer is superimposed to form a three-dimensional prototype. After the prototype is removed from the resin, it is cured, polished, and then electroplated, painted, or painted to produce the desired product.

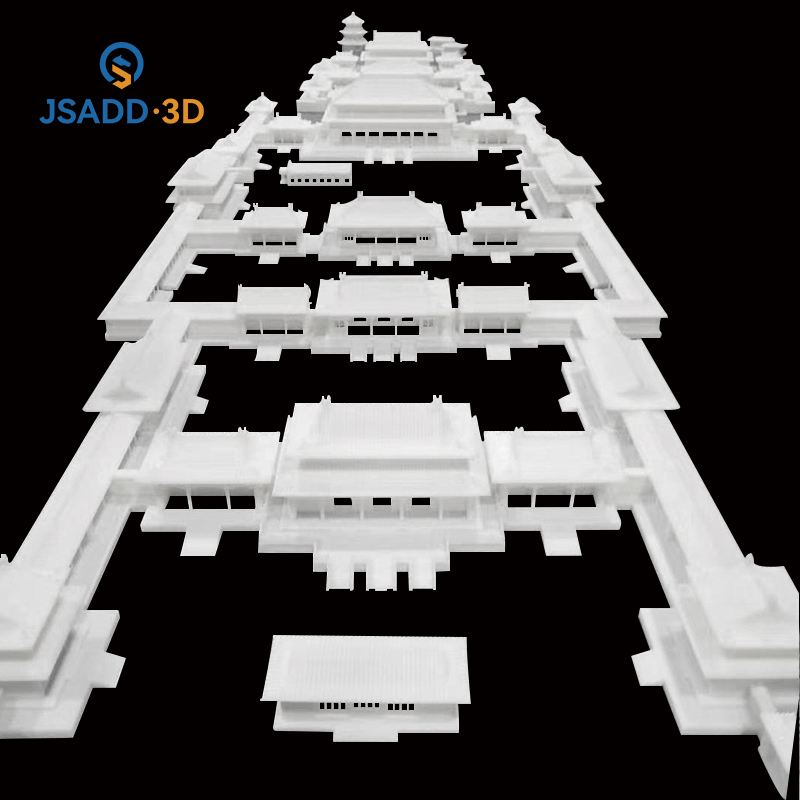

SLA technology is mainly used to manufacture a variety of molds, models, etc. It is also possible to replace the wax mold in investment precision casting with SLA prototype mold by adding other components to the raw material. SLA technology has faster forming speed and higher accuracy, but due to the shrinkage of resin during curing, stress or deformation will inevitably occur. Therefore, the development of shrink, fast curing, high strength photosensitive materials is its development trend.

Advantages of SLA technology:

1. The light-curing forming method was the first rapid prototyping process to emerge and is highly mature and time-tested.

2. Prototypes are made directly from CAD digital models, resulting in fast processing speeds and short production cycles without the need for cutting tools and molds.

3. Prototypes and molds that are complex in structure and shape or difficult to shape by traditional means can be processed.

4. Make CAD digital model intuitive and reduce the cost of error repair.

5. Provides specimens for experimentation and allows verification and calibration of the results of computer simulation calculations.

6. Can be operated online and remotely controlled, facilitating the automation of production.