Selective Laser Sintering (SLS) is a powerful 3D printing technology that belongs to the family of powder bed fusion processes, which can produce highly accurate and durable parts that can be used directly for end-use, small batch production or hand prototypes. During the SLS machine printing process, a high-powered laser is used to fuse small particles of plastic powder into the desired three-dimensional shape. The laser selectively fuses the powder material by scanning a three-dimensional data section of the powder bed surface. After scanning each cross section, the powder bed is reduced by one layer of thickness, a new layer of material is added on top of it and the selective laser sintering process is repeated until the part is complete.

SLS 3D printing can be used for both prototyping functional polymer components and small production runs, as it offers a high degree of design freedom, high precision and produces parts with good and consistent mechanical properties.

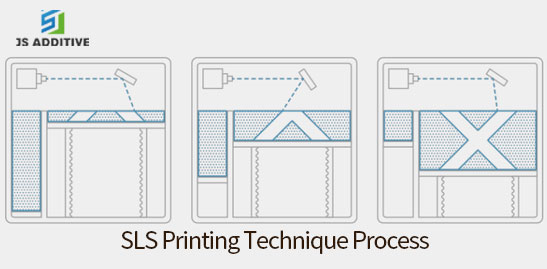

The process of SLS printing

(Picture: SLS Printing Process)

First, the powder bin and the construction area are heated close to the melting temperature of the material, and a layer of powder material is laid.

Second, the laser is then used to scan the cross-section of the layer, so that the powder temperature rises to the melting point, and selectively sintering the area that needs to be printed, forming a bond.

Third, After the completion of sintering, the construction platform is moved down, and the scraper is laid with another layer of powder material, repeating step two until the whole model is completed.

Four, after the printing is completed, the forming bin has cooled (generally below 40 degrees), and the parts can be taken out and subsequent processing can be done.

This is our SLS printing process. For more information, please visit our website www.jsadditive.com

Contributor: Alisa