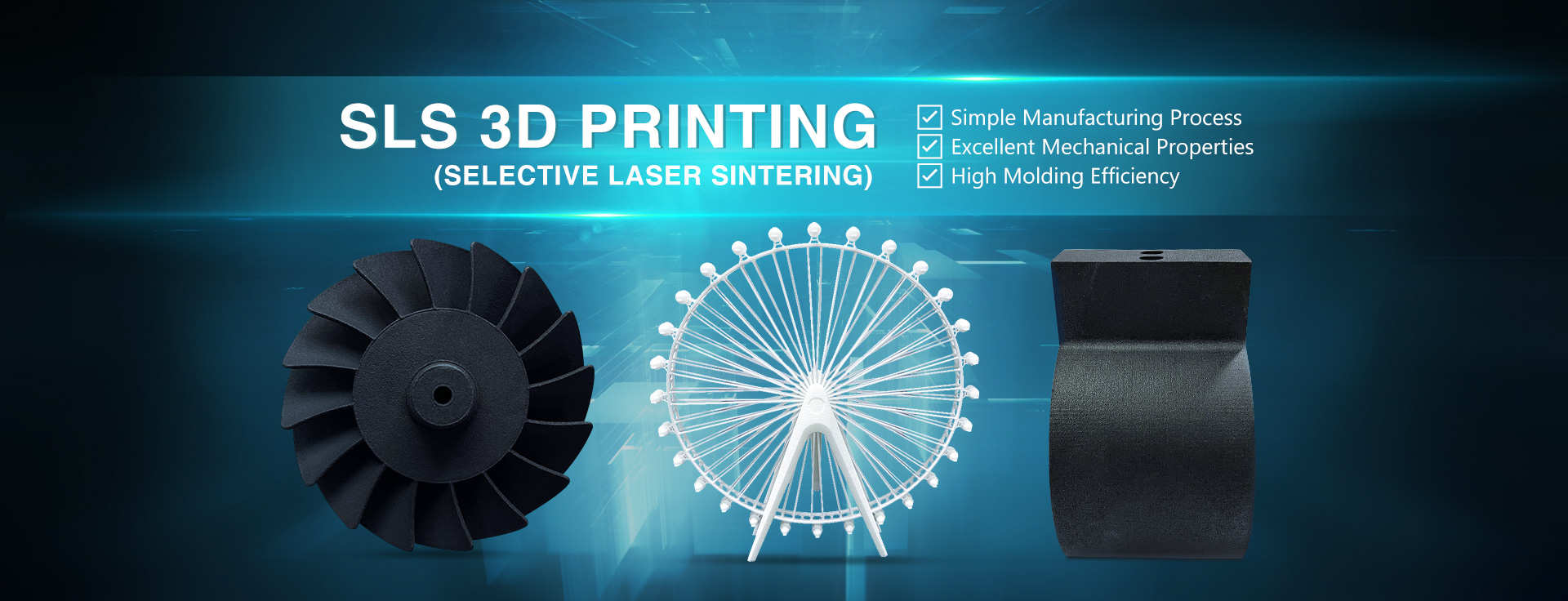

Rapid 3D Prototyping - China Manufacturers, Factory, Suppliers

Rapid 3D Prototyping, , , ,. The product will supply to all over the world, such as Europe, America, Australia,, ,, .

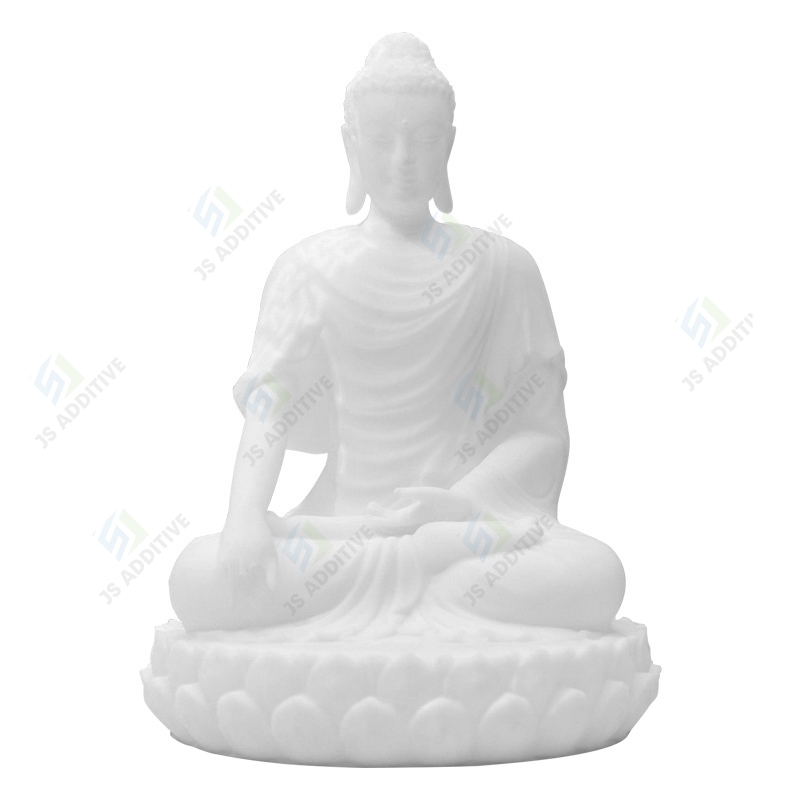

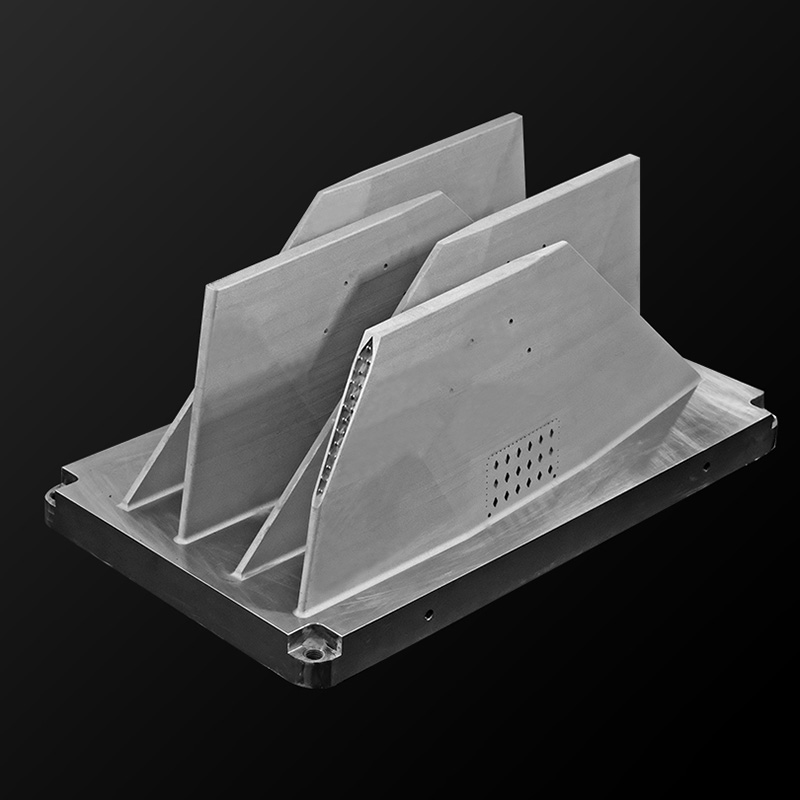

Related Products

Top Selling Products

-

Whatsapp

-

Phone

-

E-mail

-

WeChat

WeChat

-

Top