Professional 3D Printing Service

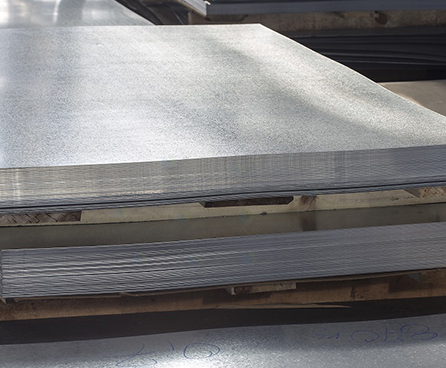

The introduction of Sheet Metal

Sheet Metal is a comprehensive cold working process for sheet metal including shearing, punching/cutting/compounding, folding, riveting, splicing, forming (such as car body), etc. Its remarkable feature is that the thickness of the same part is the same.

Sheet metal has the characteristics of light weight, high strength, electrical conductivity (can be used for electromagnetic shielding), low cost, and good mass production performance.

Here's how it works.

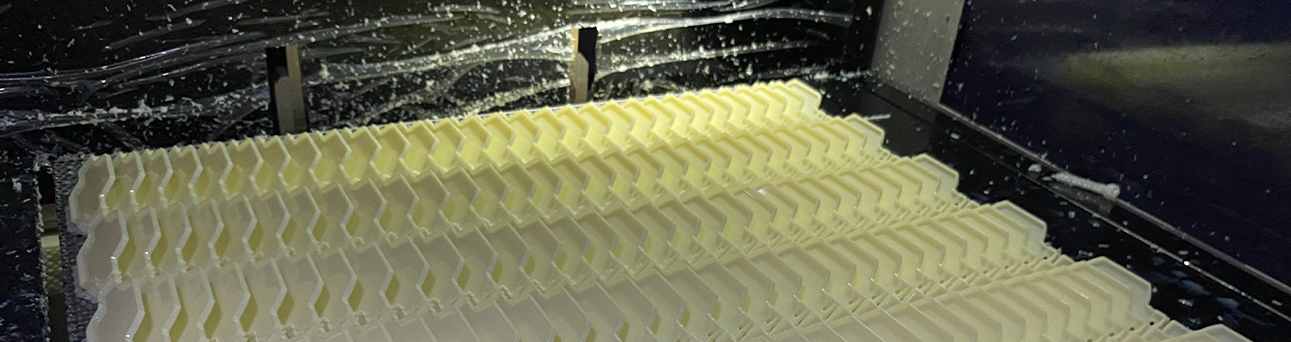

The laser (set wavelength) is irradiated on the surface of the photosensitive resin, causing the resin to polymerize and solidify from point to line and line to surface. After the first layer is cured, the working platform vertical drop a layer thickness height, scraper scraping the top layer of the resin level, continue to scan the next layer of curing, firmly glued together, finally form the 3D model we want.

Stereolithography requires support structures for overhangs, which are built in the same material. The required supports for overhangs and cavities are automatically generated, and later manually removed.

Advantages

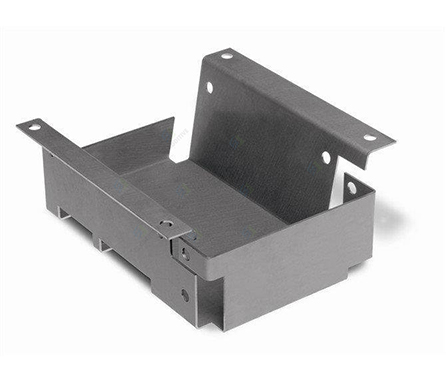

- Compared with other cutting processes, sheet metal technology has advantages such as high speed, high precision and high adaptability, fine cutting seam, small heat-affected zone (small deformation), good quality of cutting end face, and grouped welding seam. And the performance of final product is similar to the material; and the processing only needs a simple fixture, no mold, and it can replace the processing method of using complex mold punching and greatly shorten the production cycle and reduce production costs.

Disadvantages

- Cutting machine is mainly for straight cutting and can only be used for the processing of straight cutting plates;

- Punching machine has restrictions on the cutting of steel plates with a thickness greater than 1.5mm, the surface quality is not good, the cost is high, the noise is large, and it is not conducive to environmental protection;

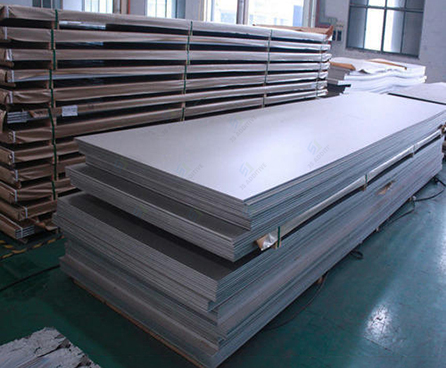

Industries with Sheet Metal

● STAINLESS STEEL; ● COLD ROLLING STEEL; ● ALUMINUM; ● SPGC ● HOT ROLLING STEEL ● COPPER

Post Processing

Since the models are printed using Sheet Metal technology, they can be easily sanded, painted, electroplated or screen printed.

Sheet Metal Materials

Only black PA12

Updating

-

Whatsapp

-

Phone

-

E-mail

-

WeChat

WeChat

-

Top