The Introduction Of SLA 3D Printing

SLA-the full name is Stereolithography Appearance, also called Laser Rapid Prototyping. It is the first of the additive manufacturing processes collectively known as “3D printing”, which has been the most mature and widely used process. playing an important role in the creative design, dental medical, industrial manufacturing, animation handwork, college education, architectural models, jewelry molds, personal customization and other fields.

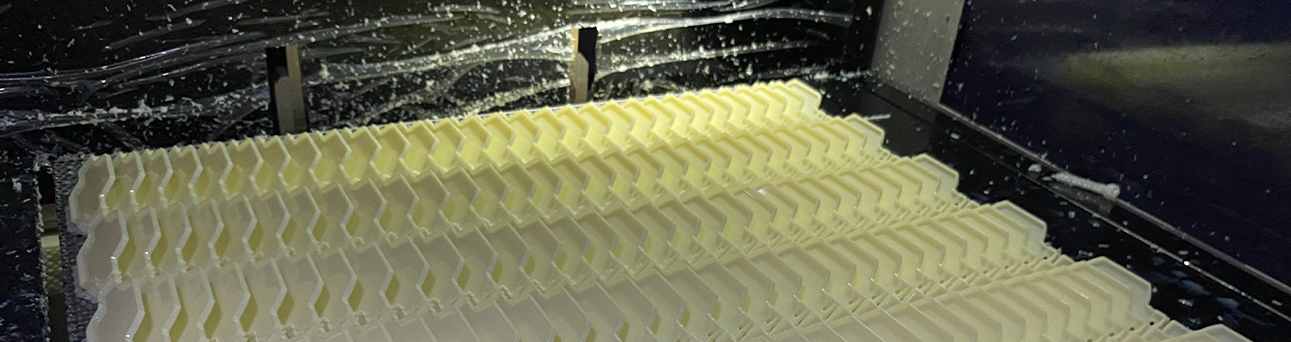

SLA is an additive manufacturing technology that works by focusing ultraviolet laser onto a vat of photopolymer resin. The resin is photo-chemically solidified and a single layer of desired 3D object is formed, the process of which is repeated for each layer until the model is completed.

Here's how it works.

The laser (set wavelength) is irradiated on the surface of the photosensitive resin, causing the resin to polymerize and solidify from point to line and line to surface. After the first layer is cured, the working platform vertical drop a layer thickness height, scraper scraping the top layer of the resin level, continue to scan the next layer of curing, firmly glued together, finally form the 3D model we want.

Stereolithography requires support structures for overhangs, which are built in the same material. The required supports for overhangs and cavities are automatically generated, and later manually removed.

Advantages

- High precision & Perfect Detail: SLA has tolerance of ±0.1mm. The minimum layer thickness of precision manufacturing can reach 0.05 mm

- Smooth Surface: They are smooth to the touch and easy to sand and paint or other post-processing

- Material Selection: Different materials can be selected according to customer requirement, like toughness, flexibility and heat resistance.

- Saving Cost: Compared with traditional CNC, SLA can save a lot of labor and time costs.

- Easily Complete Large & Complex Models: SLA has no restrictions on the structure of the model; Industrial-grade SLA printers can complete models of 1.7 meters or even larger.

- Personalization & All-in-one printing: SLA can be customized according to customer needs.

Disadvantages

- SLA parts are often fragile and not suitable for functional applications.

- Supports will appear during production, which need to be removed manually; It will leave traces of cleaning.

Industries with SLA 3D Printing

With more than 30 years of development, SLA 3D printing technology has been the most mature and the most cost-effective among various 3D printing technologies at present, widely used in many industrial fields. SLA rapid prototyping service has greatly promoted the development and innovation of these industries.

Post Processing

Since the models are printed with SLA technology, they can be easily sanded, painted, electroplated or screen printed. For most plastic materials, here are post processing techniques that are available.

SLA Materials

By SLA 3D printing, we can finish the production of large parts with good accuracy and smooth surface. There are four kinds of resin materials with specific characteristics.

| SLA | Model | Type | Color | Tech | Layer thickness | Features |

|

KS408A | ABS like | White | SLA | 0.05-0.1mm | Fine surface texture & good hardness |

|

KS608A | ABS like | Light yellow | SLA | 0.05-0.1mm | High strength & strong toughness |

|

KS908C | ABS like | Brown | SLA | 0.05-0.1mm | Fine surface texture & clear edges and corners |

|

KS808-BK | ABS like | Black | SLA | 0.05-0.1mm | Highly accurate and strong toughness |

|

Somos Ledo 6060 | ABS like | White | SLA | 0.05-0.1mm | High Strength & toughness |

|

Somos® Taurus | ABS like | Charcoal | SLA | 0.05-0.1mm | Superior strength & durability |

|

Somos® GP Plus 14122 | ABS like | White | SLA | 0.05-0.1mm | Highly accurate and durable |

|

Somos® EvoLVe 128 | ABS like | White | SLA | 0.05-0.1mm | High strength & durability |

|

KS158T | PMMA like | Transparent | SLA | 0.05-0.1mm | Excellent transparency |

|

KS198S | Rubber like | White | SLA | 0.05-0.1mm | High flexibility |

|

KS1208H | ABS like | Semi-translucent | SLA | 0.05-0.1mm | High temperature ressitance |

|

Somos® 9120 | PP like | Semi-translucent | SLA | 0.05-0.1mm | Superior chemical resistance |

-

Whatsapp

-

Phone

-

E-mail

-

WeChat

WeChat

-

Top