Advantages

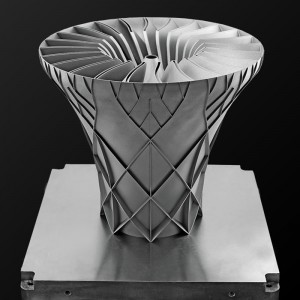

• Superior strength and durability

• Wide range of applications

• Excellent surface and large part accuracy

• Heat tolerance up to 90°C

•Thermoplastic-like performance, look and feel

Ideal Applications

• Customized end-use parts

• Tough, functional prototypes

• Under the hood automotive parts

• Functional testing for aerospace

• Low volume connectors for electronics

Technical Data-sheet

| LiquiD Properties | OpTicAl Properties | |||

| Appearance | bluish-black | Dp | 4.2 mils | [slope of cure-depth vs. In (E) curve] |

| Viscosity | ~350 cps @ 30°C | Ec | 10.5 mJ/cm² | [critical exposure] |

| Density | ~1.13 g/cm3 @ 25°C | Building layer thickness | 0.08-0.012mm | |

| Mechanical Properties | UV Postcure | UV & Thermal Postcure | |||

| ASTM Method | Property Description | Metric | Imperial | Metric | Imperial |

| D638-14 | Tensile Modulus | 2,310 MPa | 335 ksi | 2,206 MPa | 320 ksi |

| D638-14 | Tensile Strength at Yield | 46.9 MPa | 6.8 ksi | 49.0 MPa | 7.1 ksi |

| D638-14 | Elongation at Break | 24% | 17% | ||

| D638-14 | Elongation at Yield | 4.0% | 5.7% | ||

| D638-14 | Poisson’s Ratio | 0.45 | 0.44 | ||

| D790-15e2 | Flexural Strength | 73.8 MPa | 10.7 ksi | 62.7 MPa | 9.1 ksi |

| D790-15e2 | Flexural Modulus | 2,054 MPa | 298 ksi | 1,724 MPa | 250 ksi |

| D256-10e1 | Izod Impact (Notched) | 47.5 J/m | 0.89 ft-lb/in | 35.8 J/m | 0.67 ft-lb/in |

| D2240-15 | Hardness (Shore D) | 83 | 83 | ||

| D570-98 | Water Absorption | 0.75% | 0.70% | ||