Professional 3D Printing Service

The introduction of SLM 3D Printing

SLM is an exciting technology with numerous potential applications. As use cases grow, technology matures, and processes and materials become cheaper, we should see it become more commonplace, it is widely used in many fields.

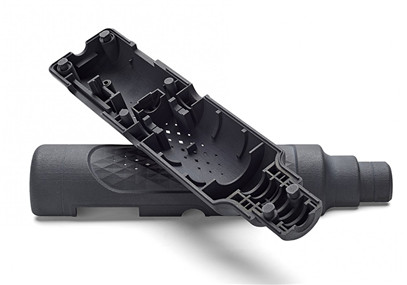

1- Undertake the next layer of unformed powder layer, prevent the laser scanning of too thick metal powder layer and collapse;

2- After the powder is heated, melted and cooled during molding process, there is shrinkage stress inside, which may cause the parts to warp, etc. The support structure connects the formed part and the unformed part, which can effectively suppress this shrinkage and keep the stress balance of the formed part. After completion, support on the model will be removed, and the surface is ground and polished with a sander. Then the model is completed.

Here's how it works.

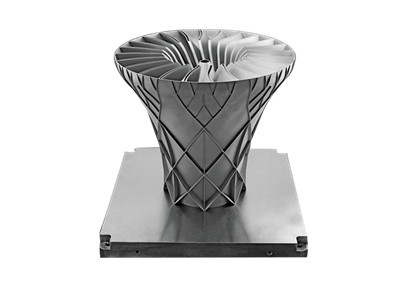

Under the control of the computer, the laser will be irradiated to the designated area, the metal powder will be melted, and the molten metal will rapidly cool and solidify. when finishing one layer, the forming substrate will lower by a layer thickness, and then a new layer of powder is applied by the scraper. The above process will be repeated until the workpiece is formed.

Advantages

- The density of standard metals processed by SLM process exceeds 99%, and the excellent mechanical properties are comparable to traditional processes

- Directly design and manufacture metal functional parts with complex geometric shapes without intermediate processes

- The types of materials being used continue to increase, and the processed parts can be welded later

- Optimize product design, replace the original solid body with a complex and reasonable structure so that the weight of the finished product is lower, thereby reducing the overall cost.

Disadvantages

- Slow printing speed and long manufacturing time.

- Rough model surface,needs post-processing to make it more beautiful.

- Rough model surface and relatively low accuracy.

Industries with SLM 3D Printing

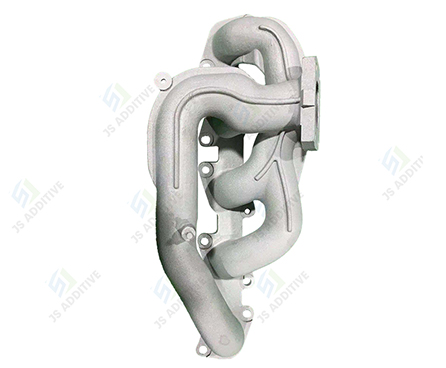

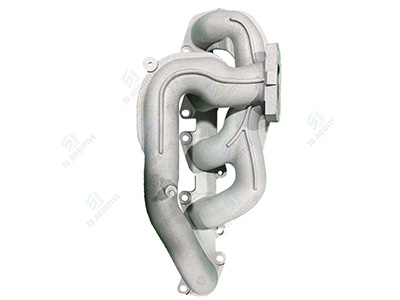

Architecture Parts / Automotive Parts / Aviation Parts (Aerospace) / Machinery manufacturing / Machinery Medical / Mould Manufacturing / Parts

Post Processing

SLM process is mainly divided into heat treatment, wire cutting metal printing, polishing , grinding, sandblasting and so on.

SLM Materials

Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS) are two metal additive manufacturing processes belonging to the powder bed fusion 3D printing family. The materials used in the process are all granular metals.

| SLM | Model | Type | Color | Tech | Layer thickness | Features |

|

Stinless Steel | 316L | / | SLM | 0.03-0.04mm | Excellent corrosion resistance Good welding performance |

|

Mould Steel | 18Ni300 | / | SLM | 0.03-0.04mm | Good mechanical properties Excellent abrasion resistance |

|

Aluminum Alloy | AlSi10Mg | / | SLM | 0.03-0.04mm | Low density but relatively high strength Excellent corrosion resistance |

|

Titanium Alloy | Ti6Al4V | / | SLM | 0.03-0.04mm | Excellent corrosion resistance High specific strength |

-

Whatsapp

-

Phone

-

E-mail

-

WeChat

WeChat

-

Top